In the rapidly evolving industrial sector, the importance of selecting the right components for fluid control systems cannot be overstated. Among these critical components, the wafer valve stands out due to its compact design and efficiency in various applications, from water treatment to chemical processing. According to the latest market research by Grand View Research, the global valve market is projected to reach $93.54 billion by 2025, with wafer valves capturing a significant share due to their versatility and ease of installation. As industries demand more sustainable and space-saving solutions, understanding the various types of wafer valves and their specific applications becomes paramount. This ultimate checklist aims to guide you through the essential factors to consider, ensuring that you select the best wafer valve tailored to your specific needs.

When selecting a wafer valve for your applications, several key factors must be prioritized to ensure optimal performance and longevity. Firstly, consider the material compatibility with the media being handled. Different applications may involve corrosive substances or high temperatures, so choosing a valve made of suitable materials—such as stainless steel or PVC—can significantly impact durability and functionality.

When selecting a wafer valve for your applications, several key factors must be prioritized to ensure optimal performance and longevity. Firstly, consider the material compatibility with the media being handled. Different applications may involve corrosive substances or high temperatures, so choosing a valve made of suitable materials—such as stainless steel or PVC—can significantly impact durability and functionality.

Another crucial element is the valve’s pressure rating. Ensure the wafer valve you select can withstand the pressure range required for your specific application. Overestimating or underestimating pressure ratings can lead to failures or inefficiencies. Always refer to the manufacturer's specifications and, if unsure, consult with an expert for guidance on the suitable rating for your system.

Tip: It's advisable to assess the installation requirements and space limitations, as wafer valves have unique space considerations compared to other valve types. Measures such as flanges and alignment can affect the overall setup, so proper planning can prevent installation headaches. When in doubt, seeking advice from a valve specialist can help streamline the selection process.

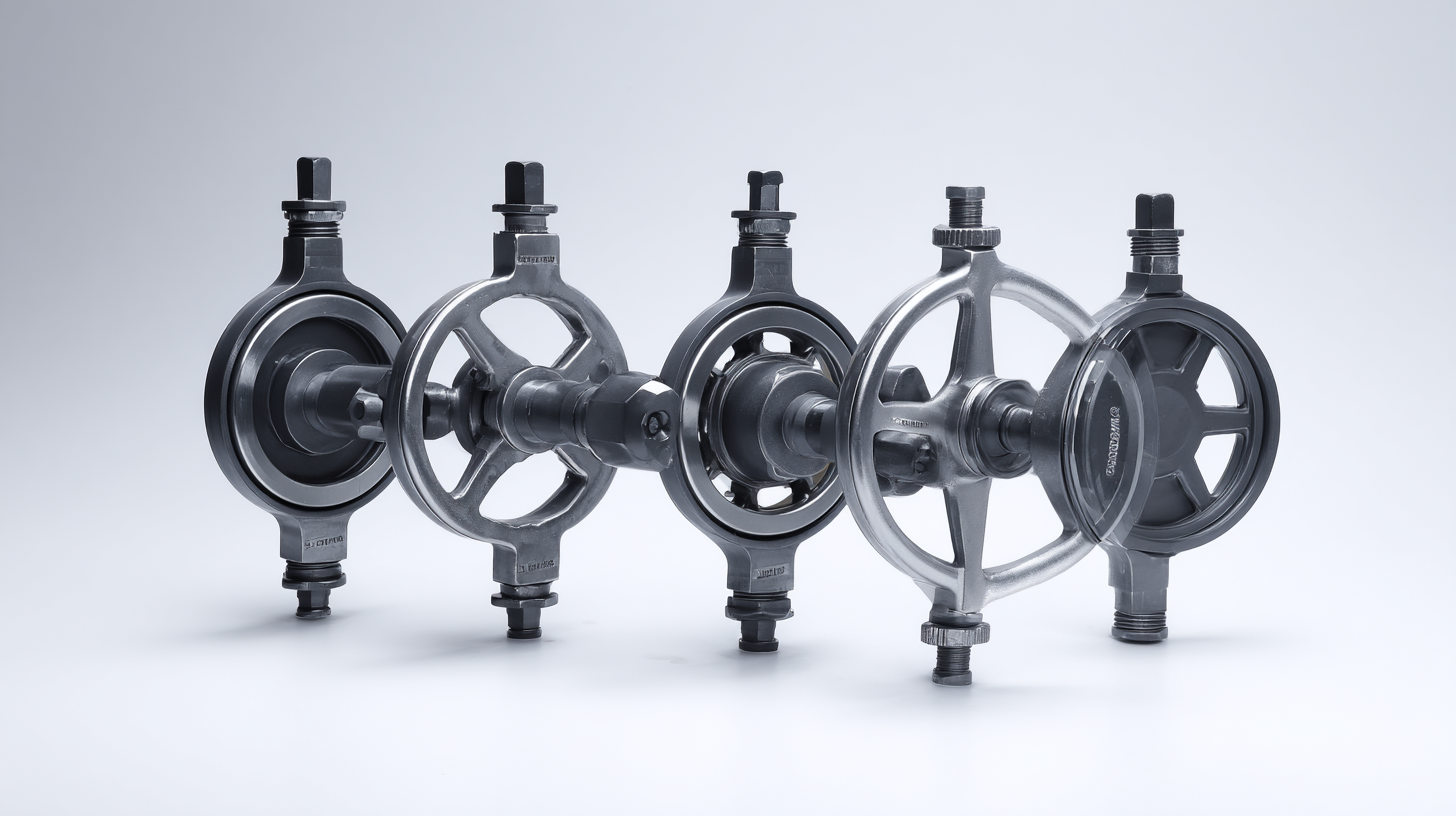

When selecting the best wafer valve for your specific application, it’s essential to understand the different types and their unique features. Wafer valves are designed for convenience and efficiency, providing a compact solution for controlling flow in various industrial settings. The most common types include butterfly valves, check valves, and gate valves, each serving distinct purposes. Butterfly valves, for instance, are ideal for throttling applications due to their quick operation and low-pressure drop, making them suitable for large-scale pipelines.

Check valves, on the other hand, play a crucial role in preventing backflow and ensuring that media flows in one direction. They are particularly effective in systems where reverse flow could cause damage or inefficiency. Gate valves, known for their ability to provide a tight seal, are perfect for applications requiring a full-flow capability without pressure loss. Understanding these differences equips you to choose the right wafer valve that aligns with your operational requirements and ensures optimal performance in your system.

| Valve Type | Material | Max Pressure (psi) | Temperature Range (°F) | Features |

|---|---|---|---|---|

| Butterfly Valve | Cast Iron | 150 | -20 to 300 | Quick opening, low torque |

| Check Valve | Stainless Steel | 200 | -50 to 400 | Prevents backflow, durable |

| Gate Valve | Brass | 250 | -20 to 250 | Full flow, high sealing capability |

| Ball Valve | PVC | 125 | -10 to 140 | Quick opening, low pressure drop |

| Globe Valve | Carbon Steel | 300 | -20 to 450 | Excellent throttling, flexible |

When selecting the best wafer valve for your needs, ensuring material compatibility with your environment is paramount. According to a report by the Valve Manufacturers Association of America, nearly 30% of valve failures are attributed to material incompatibility. Different applications may require specific materials such as stainless steel, PVC, or specialty alloys, each possessing distinct properties that affect their durability and resistance to corrosion. For instance, stainless steel valves are often favored in environments with high temperatures and pressures, while plastic valves may be suitable for less demanding applications.

When selecting the best wafer valve for your needs, ensuring material compatibility with your environment is paramount. According to a report by the Valve Manufacturers Association of America, nearly 30% of valve failures are attributed to material incompatibility. Different applications may require specific materials such as stainless steel, PVC, or specialty alloys, each possessing distinct properties that affect their durability and resistance to corrosion. For instance, stainless steel valves are often favored in environments with high temperatures and pressures, while plastic valves may be suitable for less demanding applications.

Tip: Always evaluate the chemical compatibility of valve materials with the fluids they will be handling. The Chemical Resistance Guide by the American Society for Testing and Materials provides essential data to help in selecting the right materials based on your specific conditions.

Moreover, consider the working temperature and pressure ranges. A study published by the International Society of Automation indicates that operating valves outside their recommended specifications can lead to premature failure. Materials with high tensile strength, such as Duplex stainless steel, offer enhanced performance in extreme environments, making them a solid choice for critical applications.

Tip: Review the manufacturer's guidelines and technical specifications thoroughly to ensure optimal performance. Seeking advice from industry experts can also aid in making informed decisions tailored to your unique operational needs.

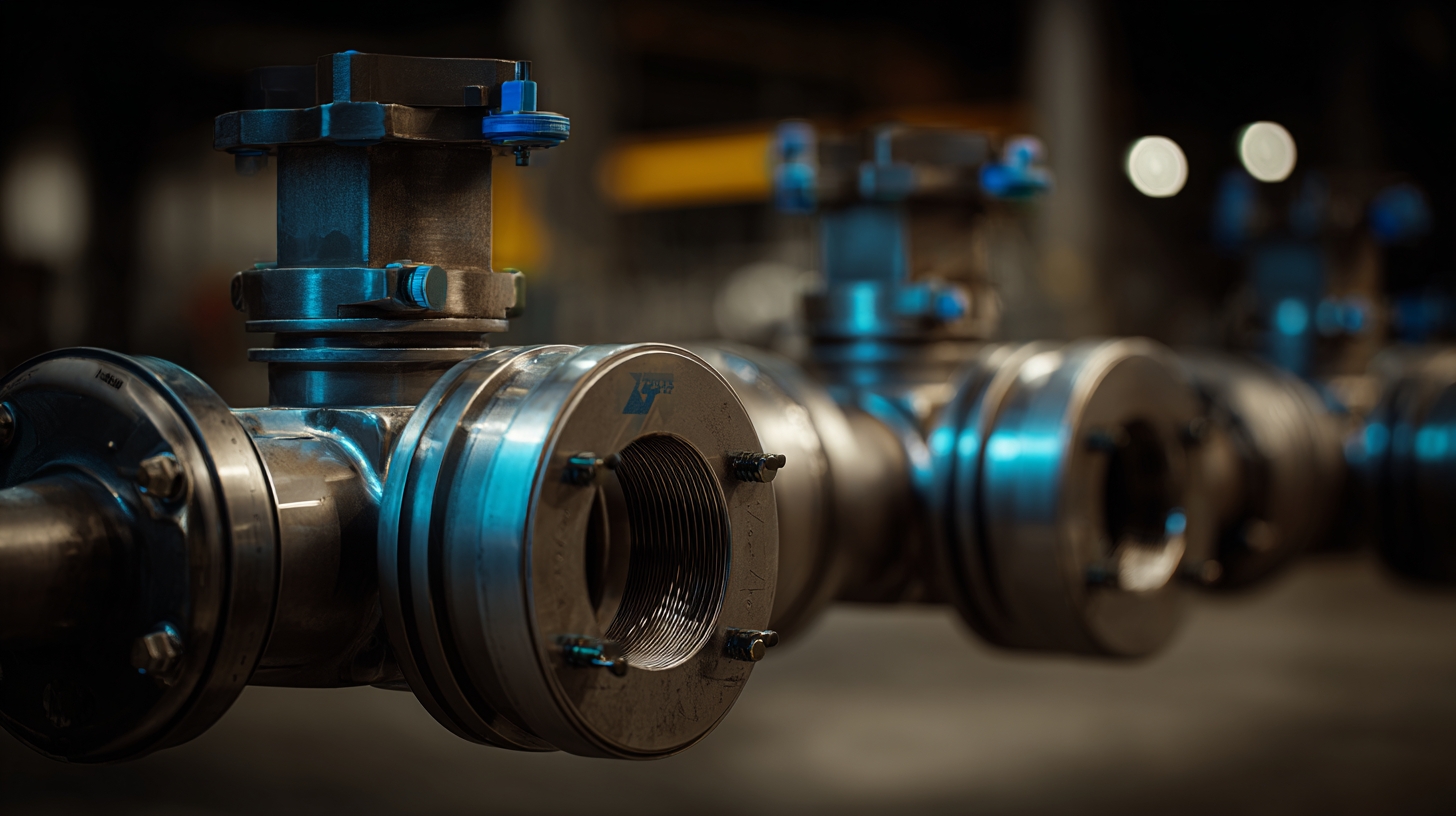

When selecting a wafer valve, proper installation and diligent maintenance are crucial for ensuring optimal performance. First, before installation, it is essential to thoroughly clean the piping system to remove any debris or contaminants that could compromise the valve's efficiency. Proper alignment of the valve between the flanges is critical; misalignment can lead to wear and leaks over time. Always refer to the manufacturer's specifications regarding torque settings for the bolts, as these ensure the valve is secured without damaging the gasket.

Once installed, regular maintenance checks should be conducted to monitor the valve's performance. Inspecting the seals and gaskets for signs of wear is vital since degradation can lead to leaks. Lubrication of moving parts should follow the guidelines provided in the valve’s manual, as this can help prevent corrosion and ensure smooth operation.

Additionally, operational checks should be performed to confirm that the valve opens and closes smoothly, indicating that the internal components are functioning well. By following these installation and maintenance tips, you can significantly enhance the longevity and effectiveness of your wafer valve.

When selecting a wafer valve, a deep dive into cost analysis is essential. Finding the right balance between quality and affordability can significantly impact the overall performance and lifespan of your valve. High-quality wafers tend to come at a premium, but investing in them often proves beneficial in the long run. It's crucial to consider the specific requirements of your application and assess whether the more costly valve provides substantial benefits that justify the expense.

Tips for navigating this balance include evaluating the total cost of ownership rather than just the upfront price. Consider factors such as expected maintenance costs, energy efficiency, and potential downtime. Another tip is to compare different manufacturers and their offerings, as prices can vary significantly, yet their quality might meet the same standards.

Finally, don't hesitate to request samples or trial units from suppliers. This can help you assess the valve's performance without committing to a large purchase. By thoroughly evaluating these aspects, you can make an informed decision that meets both your functional and budgetary needs.

Same Day Shipping

ISO Certified Production