In the world of industrial piping and fluid control, the importance of selecting the right valve cannot be overstated. Among various types of valves, globe valves stand out due to their exceptional ability to regulate flow. According to John Smith, a renowned expert in valve engineering, "Choosing the right globe valve for your application can significantly enhance efficiency and safety in your operations." This statement underscores the critical nature of making informed decisions when it comes to globe valves.

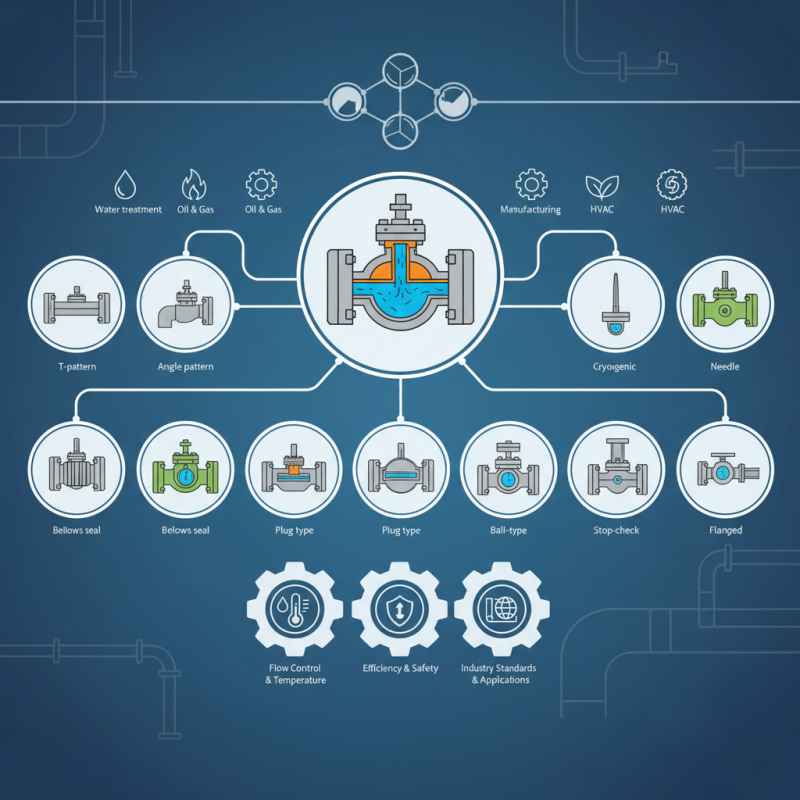

Globe valves, characterized by their spherical body shape and ability to provide precise flow control, play a key role in various industrial applications, from water treatment facilities to oil and gas refineries. As industries continue to evolve and demand more efficient piping solutions, understanding the different types of globe valves available is crucial. This guide aims to provide a comprehensive overview of the top 10 globe valves, along with essential factors to consider in order to make the most suitable choice for your specific needs. By delving into the features, benefits, and applications of each valve type, we empower professionals to enhance their systems while adhering to industry standards.

Globe valves are vital components in various industrial applications, primarily used for regulating flow within piping systems. They feature a spherical body shape, which houses an internal baffle or disc that moves to restrict or open the flow, making them ideal for throttling services. According to a report by Global Market Insights, the globe valve market is expected to see substantial growth, projected to reach USD 10 billion by 2027, driven by increasing demand in oil and gas, water treatment, and power generation sectors.

The functionality of globe valves is particularly advantageous in applications where precise flow control is essential. Unlike gate valves, which are mainly suited for on/off services, globe valves provide superior performance in adjusting flow rates, thus enhancing process efficiency. Additionally, they offer better sealing properties, minimizing leaks due to their design which allows for a tighter fit when closed. A technical study published by the American Society of Mechanical Engineers (ASME) indicates that the flow characteristics of a globe valve can achieve up to 90% efficiency in throttling applications, highlighting their importance in critical operational environments. This capability to maintain effective flow regulation under varying pressure conditions solidifies the globe valve's role in numerous engineering designs.

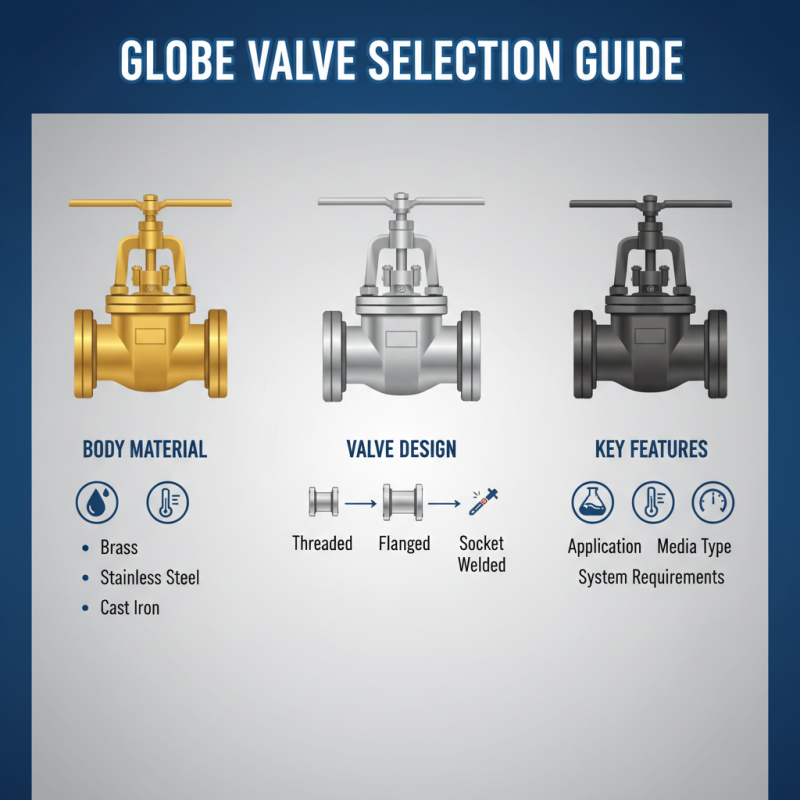

When selecting the right globe valve, understanding its key features is crucial to ensuring optimal performance in your system. One of the most important characteristics is the valve body material, which should be chosen based on the application and media being handled. Common materials include brass, stainless steel, and cast iron, each offering different levels of resistance to corrosive environments, pressures, and temperatures. Additionally, the design of the valve, whether it's a threaded, flanged, or socket weld connection, should align with your piping system requirements.

Another essential aspect to consider is the valve size and flow characteristics. Globe valves typically offer good throttling capability, making them preferable for applications requiring flow regulation. The diameter of the valve should match the piping to ensure efficient flow rates. Furthermore, look for valves with features such as handwheels or actuators that allow for smoother operation. Understanding these features not only aids in choosing the right globe valve but also enhances the overall efficiency and longevity of the flow control in your system.

Globe valves are essential components in various industrial applications, serving primarily to regulate fluid flow. Understanding the different types of globe valves is crucial for selecting the right one for any specific system. Generally, globe valves can be categorized into three main types based on their design and functionality: standard globe valves, angle globe valves, and blow-off globe valves.

Standard globe valves feature a linear motion mechanism that provides precise flow control, making them ideal for applications requiring throttling. Angle globe valves, on the other hand, are designed with a 90-degree turn that allows for a more streamlined flow path, which can be beneficial in applications where space is limited. Lastly, blow-off globe valves are specifically designed to facilitate draining or blow-off operations, helping to maintain system integrity by allowing for easy removal of sediment or contaminants that may accumulate over time. Understanding these variations helps engineers and operators choose the right type of globe valve that meets their specific operational needs and efficiency requirements.

| Type | Material | Pressure Rating | Size Range | Applications |

|---|---|---|---|---|

| Globe Valve | Cast Iron | 150 psi | 1" - 12" | Water Supply Systems |

| Globe Valve | Stainless Steel | 300 psi | 1/2" - 6" | Chemical Processing |

| Pressure Seal Globe Valve | Carbon Steel | 600 psi | 2" - 24" | High-Pressure Systems |

| Forged Steel Globe Valve | Forged Steel | 900 psi | 1" - 8" | Oil and Gas Industry |

| Split Body Globe Valve | Ductile Iron | 150 psi | 1" - 14" | Fire Protection Systems |

| Y-Type Globe Valve | Bronze | 200 psi | 1/4" - 3" | Heating Systems |

| Angle Globe Valve | Plastic | 50 psi | 1" - 4" | Water Treatment |

| Electric Globe Valve | Aluminum | 150 psi | 1" - 6" | Automation Systems |

| Pneumatic Globe Valve | Stainless Steel | 100 psi | 1" - 10" | Industrial Applications |

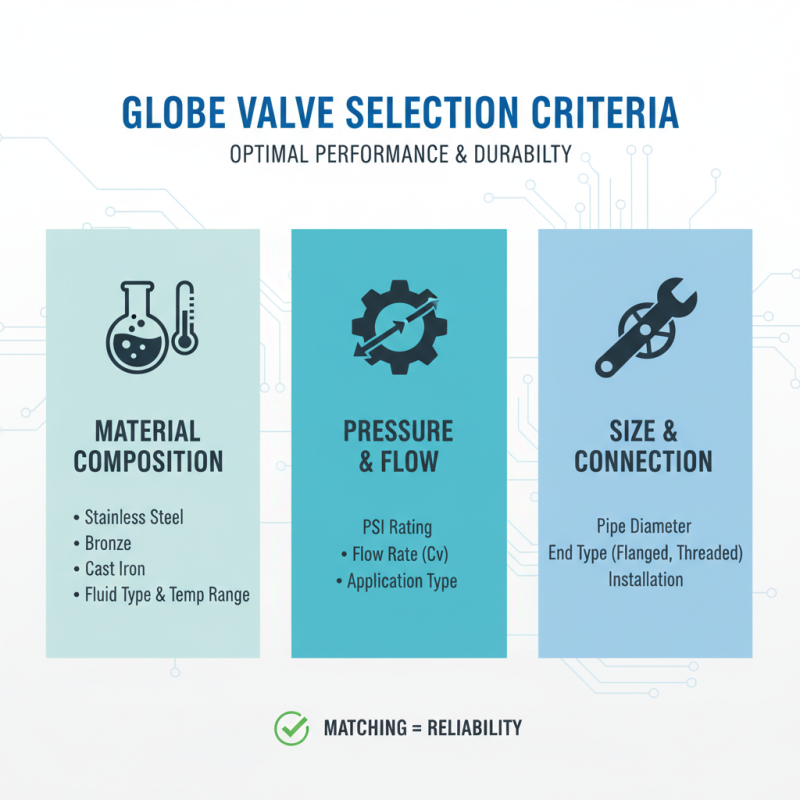

When selecting the right globe valve for a specific application, several key criteria must be taken into consideration to ensure optimal performance and durability. Firstly, the valve's material composition is crucial, as it impacts both corrosion resistance and temperature tolerance. Materials such as stainless steel, bronze, and cast iron are commonly used, but the choice ultimately depends on the nature of the fluid being controlled, including its chemical properties and temperature range. It is essential to match the material with the operating conditions to prevent premature failures and ensure long-lasting functionality.

Another important factor is the valve size and connection type, which must align with the existing piping system. The dimensions of the globe valve should correspond to the diameter of the pipelines to maintain fluid flow efficiency and prevent bottlenecks. Additionally, consider the type of end connections, such as threaded, flanged, or welded, ensuring compatibility with your installation requirements. The pressure rating of the valve should also be evaluated, as it determines the valve's ability to withstand the operating pressures of the system without leaking or failing. By carefully assessing these criteria, users can select the most suitable globe valve for their specific needs, leading to improved system performance and reliability.

Globe valves are crucial components in various industries due to their ability to provide precise flow control. According to the Global Globe Valve Market report, the demand for these valves is projected to grow at a CAGR of 4.5% over the next five years, reflecting their increasing importance in sectors such as oil and gas, water management, and chemical processing. In the oil and gas industry, globe valves are often used in critical applications, including wellhead control and pipeline management, where reliable performance is essential to ensure the safety and efficiency of operations.

In the chemical processing industry, globe valves play a vital role in handling corrosive substances and ensuring accurate throttling of flow rates. The Chemical & Engineering News (C&EN) highlights that globe valves are preferred for their sturdy construction, which can endure high pressures and temperatures. They facilitate the smooth operation of processes involving reactive chemicals, thereby minimizing the risk of leaks and spills. Furthermore, in water treatment and distribution systems, the reliable shut-off and regulation capabilities of globe valves contribute significantly to maintaining water quality and optimizing system performance. The versatility and robustness of globe valves thus make them indispensable across various applications, underscoring their value in industrial operations.

Same Day Shipping

ISO Certified Production