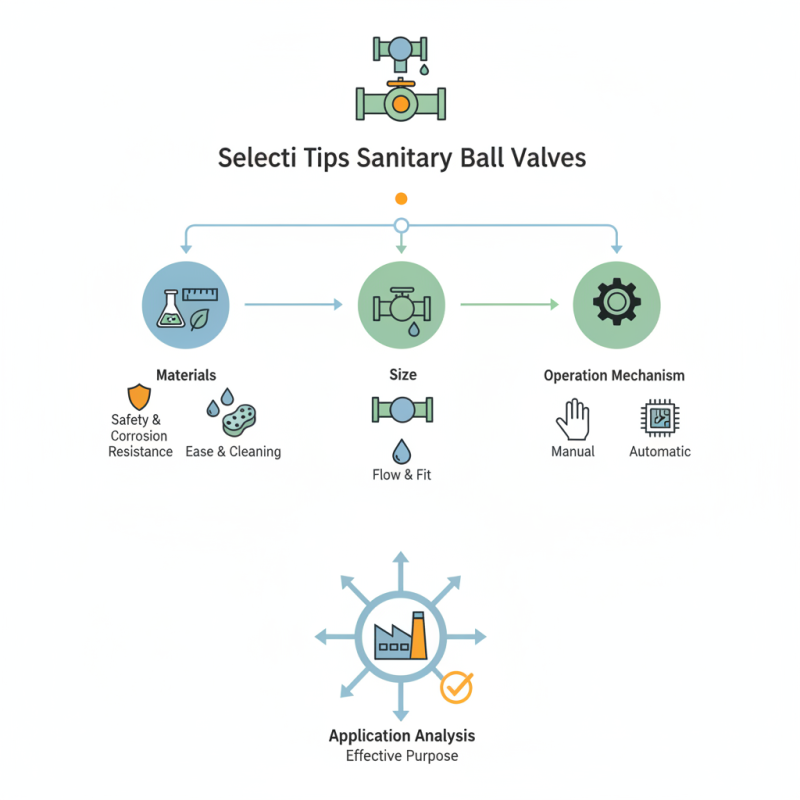

Choosing the right sanitary ball valve is critical in many industries. These valves ensure hygiene and efficiency in fluid systems. A sanitary ball valve is designed to handle the specific requirements of food, beverage, and pharmaceutical applications. When selecting a valve, the materials used are essential. They should be compliant with safety standards and resistant to corrosion. Consider how easy it is to clean these valves, as sanitation is paramount.

Another factor is the size of the valve. It should fit the existing piping system without compromising flow. A poorly fitted valve can lead to costly leaks or contamination. Moreover, examine the valve's operation mechanism. Manual or automatic options may better suit specific processes.

Choosing the right valve requires careful consideration. Take time to analyze the application requirements thoroughly. Mistakes in selection can lead to operational challenges. Learning from these experiences is essential for future purchases. A thoughtful approach ensures that your sanitary ball valve serves its purpose effectively.

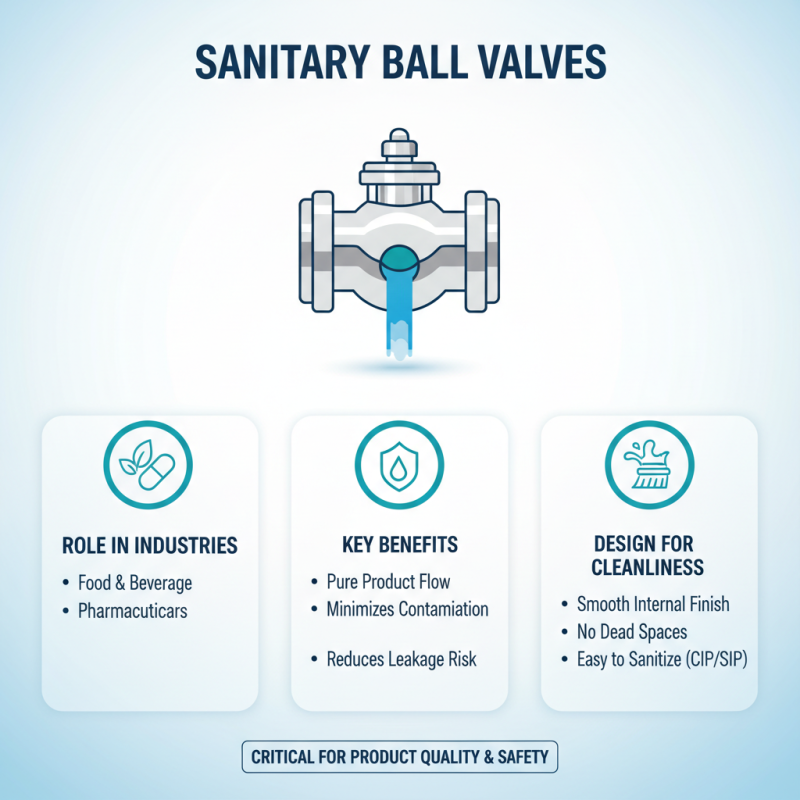

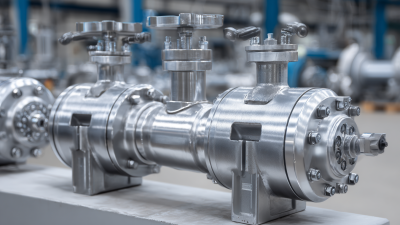

Sanitary ball valves play a critical role in various industries, especially in food and pharmaceuticals. Their design ensures a clean and efficient flow of liquids, minimizing contamination risks. Cleanliness is vital here. When dealing with sensitive products, any leakage or bacteria can compromise quality.

These valves are made from smooth materials, which help in easy cleaning. This feature is important in environments where hygiene is essential. However, not all materials are created equal. Some may wear down faster than expected. Understanding the specific application is crucial.

Choosing the right valve can be complex. It’s essential to consider size, pressure ratings, and intended use. A valve that works well in one scenario may fail in another. Pay attention to maintenance needs too. A valve that seems easy to use may require more effort to keep clean. Evaluating all these aspects leads to smarter choices in sanitary ball valves.

Choosing the right sanitary ball valve is crucial for any system. Key factors should guide your decision. Assess the material of the valve. Stainless steel is often preferred for its durability and resistance to corrosion. Think about the fluid type flowing through the valve. Compatibility is essential for optimal performance.

Consider the size and pressure ratings as well. A valve that’s too small can restrict flow. High pressure requires sturdier materials. Certification matters as well. Look for valves that meet industry standards. This ensures they are safe and reliable.

Think about the end connections. Whether you need tri-clamp or welded ends, proper compatibility is vital. Installing the wrong type could lead to leaks. Also, reflect on how often you need to service the valves. Some require frequent maintenance, which can be a hassle. Remember, not all valves handle all conditions perfectly. Take your time to choose wisely.

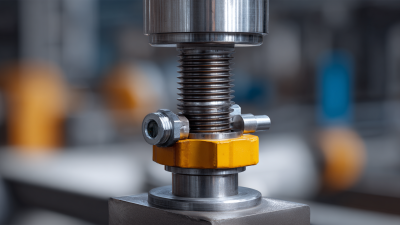

When selecting a sanitary ball valve, material and construction are critical factors. Stainless steel is a common choice for its durability and resistance to corrosion. Look for valves made from 316L stainless steel, which offers better performance in various sanitary applications.

Tip: Always consider the temperature and pressure requirements of your system. Improper material choice could lead to valve failure over time. Some plastics may suit certain applications but could degrade under high temperatures or pressures.

Another aspect to consider is the valve's design. Ensure a smooth interior finish to minimize the risk of contamination. Welded or clamp connections can provide better sealing compared to threaded options.

Tip: Pay attention to the certifications of the valve. Ensure that it meets the relevant sanitary standards for your industry. Non-compliance could lead to costly reworks or safety issues. Balancing these factors may not be easy, but it is essential for ensuring product integrity.

When selecting sanitary ball valves, the size and fit matter significantly. These valves come in various sizes, affecting their performance in piping systems. According to industry reports, improper sizing can lead to inefficiencies, resulting in up to a 25% decrease in system performance. It is crucial to measure your piping correctly. Some users underestimate the importance of a proper seal, which can lead to leaks and contamination.

Additionally, consider the connection types. Flanged connections can be bulkier, while tri-clamp options offer easier maintenance. Studies indicate that 15% of system failures are linked to poor fitting connections. It's essential to analyze your specific application, as different industries have unique requirements. For example, a dairy processing plant might prioritize a tighter fit to maintain cleanliness and safety.

When evaluating size, also account for flow rates. Some valves may seem fitting based on size alone, yet fail to meet required pressure drops. Reports suggest that 10% of users have faced operational issues due to miscalculating these factors. Taking the time to assess both dimensions and operational criteria can serve to enhance reliability and performance in the long run.

When selecting sanitary ball valves, maintenance and compliance should be top priorities. These valves play a crucial role in various industries, especially where hygiene is vital. Regular inspection can prevent costly failures. Also, consider the materials used. Stainless steel or other non-corrosive materials should be prioritized to ensure longevity.

Proper maintenance includes routine lubrication and visual inspections. Some users overlook this, leading to premature wear. Cleaning protocols matter too. Establish a cleaning schedule that aligns with your operational demands. Inadequate cleaning can cause contamination, which may breach compliance requirements.

Tip: Regularly check seals and gaskets for wear. This small step can significantly enhance valve performance. Assess if the valve meets industry standards. Identifying any discrepancies early can save time—and money—down the line. Ensure your staff is trained. Understanding proper handling can make a significant difference. Inconsistencies here can impact overall safety and efficiency.

| Feature | Consideration | Maintenance Tips | Compliance Factors |

|---|---|---|---|

| Material Compatibility | Ensure it matches the fluids | Regularly check for corrosion | Verify FDA compliance |

| Size and Pressure Ratings | Match the system specifications | Inspect for leaks regularly | Ensure compliance with applicable standards |

| End Connection Type | Select suitable connection methods | Check alignment of connections | Follow industry standards for connections |

| Actuation Method | Consider manual or automated options | Ensure smooth operation | Confirm actuator compliance with regulations |

| Serviceability | Choose valves with easy access | Schedule routine maintenance | Keep records for compliance audits |

Same Day Shipping

ISO Certified Production