In recent years, the global demand for butterfly valves has surged, driven by the expanding industrial sectors such as oil and gas, water management, and HVAC systems. According to a report by MarketsandMarkets, the butterfly valve market is projected to reach USD 6.9 billion by 2025, growing at a CAGR of 4.8%. This growth is attributed to the valves’ various advantages, including lightweight design, low pressure drop, and efficient flow control. As businesses increasingly seek to capitalize on the opportunities presented by this thriving market, it has become essential to implement effective sourcing strategies.

By leveraging comprehensive market analysis, establishing strong supplier relationships, and ensuring compliance with international standards, companies can secure high-quality butterfly valves that meet their operational needs while optimizing costs. This blog will explore the top strategies for sourcing butterfly valves in global markets, providing insights that can enhance procurement efficiency and product quality.

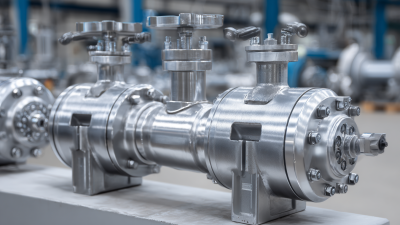

When examining butterfly valve types, a comprehensive overview reveals the diversity and functionality of these essential flow control devices. Butterfly valves are characterized by their simple design, which includes four main components: the body, stem, disc, and metal seal. This configuration allows for effective fluid regulation, making them an ideal choice in various applications, from water treatment facilities to large dams. The global market for butterfly valves is poised for significant growth, projected to reach approximately USD 11.7 billion by 2025, with a robust CAGR of 6.5% over the next decade. This robust demand reflects the increasing focus on efficient fluid management systems across industries.

When examining butterfly valve types, a comprehensive overview reveals the diversity and functionality of these essential flow control devices. Butterfly valves are characterized by their simple design, which includes four main components: the body, stem, disc, and metal seal. This configuration allows for effective fluid regulation, making them an ideal choice in various applications, from water treatment facilities to large dams. The global market for butterfly valves is poised for significant growth, projected to reach approximately USD 11.7 billion by 2025, with a robust CAGR of 6.5% over the next decade. This robust demand reflects the increasing focus on efficient fluid management systems across industries.

Different types of butterfly valves, such as concentric, double eccentric, and triple eccentric valves, cater to specific operational needs. The concentric butterfly valve offers a cost-effective solution for low-pressure applications, while the double eccentric variant minimizes wear and provides better sealing under high-pressure conditions. The triple eccentric design further enhances performance, especially in high-temperature applications, by reducing friction and extending valve lifespan. Understanding these distinctions is crucial for selecting the best butterfly valve to meet the rigorous demands of modern hydraulic systems, particularly in flood control applications, where reliable performance is paramount.

When sourcing butterfly valves in global markets, there are several key factors to consider to ensure you are making the best decision for your applications. The first aspect is understanding the specifications that meet your operational needs. This includes factors such as pressure ratings, temperature tolerances, and the materials used in the construction of the valves. Selecting the appropriate valve type is crucial, as it directly affects the efficiency and safety of your system.

Another vital consideration is the supplier’s reputation and reliability. Look for manufacturers with a proven track record in producing high-quality butterfly valves. Assessing customer reviews, certifications, and industry experience can provide insights into the supplier's reliability. Furthermore, it's important to evaluate the availability of technical support and after-sales service, as these factors can significantly impact long-term maintenance and operation. Keeping these elements in mind can help streamline the sourcing process and ensure you invest in valves that deliver value and performance over time.

When sourcing butterfly valves for global markets, evaluating quality and performance standards is paramount. The primary focus should be on materials and construction methods. High-performance butterfly valves often utilize advanced materials like stainless steel or ductile iron, which not only enhance durability but also resist corrosion. Understanding the specific application environment—whether it involves high-pressure systems or aggressive media—will guide the selection process, ensuring that the chosen valve can withstand operational demands.

Another crucial aspect is compliance with international standards. Look for valves that meet or exceed certifications such as ISO, API, or ASME. These standards ensure that the valves have undergone rigorous testing for reliability and performance. Additionally, consider the valve's design for ease of maintenance and operational efficiency. Features such as resilient seat design or a streamlined flow path can significantly affect long-term performance and reduce operational costs, making them essential criteria in your evaluation process.

The following chart illustrates the evaluation of various performance parameters for butterfly valves sourced from global markets, emphasizing key standards such as durability, flow efficiency, and weight.

When it comes to sourcing butterfly valves in global markets, finding reliable suppliers is crucial for ensuring quality and performance. A solid global sourcing strategy begins with comprehensive market research. Identify regions that are known for manufacturing high-quality butterfly valves, such as Asia and Europe. Utilize online platforms and trade directories to compile a list of potential suppliers, and take the time to read reviews and testimonials to gauge each supplier's reputation.

Once you have a list, reach out to these suppliers for quotations and sample products. This not only allows you to assess the quality of their offerings but also provides insights into their responsiveness and customer service. It's essential to engage in direct communication with suppliers to establish a better understanding of their production capabilities, lead times, and compliance with international standards. Building strong relationships with suppliers fosters transparency and reliability, which are key components in successful global sourcing strategies for butterfly valves.

In today's dynamic global markets, sourcing the best butterfly valves requires a keen understanding of both cost and quality. As procurement professionals navigate through the complexities of valve selection, the challenge lies in balancing budget constraints with the need for high-performance products. The recent market shifts emphasize that while resilience in the supply chain remains essential, efficiency is now just as important. This dual focus encourages businesses to not only seek competitive prices but also to ensure that the valves meet stringent quality standards necessary for operational reliability.

Achieving optimal performance while managing costs can be approached by establishing strong partnerships with suppliers who understand the nuances of the marketplace. By prioritizing a supply base that emphasizes both resilience and efficiency, organizations can secure dependable sources without compromising on quality. Utilizing advanced sourcing strategies, including leveraging technology and data analytics, can facilitate a more informed decision-making process. This not only assists in identifying high-quality butterfly valves but also helps in evaluating the total cost of ownership, ensuring that both immediate budget considerations and long-term operational efficacy are effectively addressed.

| Region | Cost Range (USD) | Quality Rating (1-10) | Lead Time (Days) | Supplier Reliability (1-5) |

|---|---|---|---|---|

| North America | 150 - 300 | 8 | 15 | 4 |

| Europe | 180 - 350 | 9 | 10 | 5 |

| Asia-Pacific | 100 - 250 | 7 | 20 | 3 |

| South America | 200 - 400 | 6 | 30 | 3 |

| Middle East | 220 - 450 | 8 | 25 | 4 |

Same Day Shipping

ISO Certified Production