In the realm of fluid dynamics, the choice of components significantly impacts system efficiency and reliability. Swing check valves are crucial in preventing backflow in many applications, ensuring that the flow remains unidirectional. According to a report by MarketsandMarkets, the global valve market is expected to grow from USD 73.8 billion in 2020 to USD 94.2 billion by 2025, with swing check valves playing a vital role in this expansion due to their effectiveness in maintaining optimal flow control. With numerous varieties and specifications available, selecting the right swing check valve becomes imperative for engineers and system designers. This blog will explore top strategies for choosing the ideal swing check valve, emphasizing the critical factors that influence performance and longevity in varied operational contexts.

Swing check valves are essential components in many fluid systems, allowing for optimal flow control while preventing backflow. These valves operate using a hinged disc that swings open and closed based on flow direction, ensuring that the fluid only moves in one way. According to a market report by Markets and Markets, the global demand for check valves is expected to grow at a CAGR of 5.3% from 2020 to 2025, driven by the rising need for efficient water and wastewater management systems.

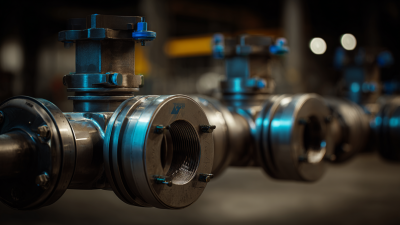

Understanding the basics of swing check valves is crucial for selecting the right one for your application. They are commonly used in a variety of industries, including oil and gas, water treatment, and HVAC systems. The American National Standards Institute (ANSI) identifies swing check valves as particularly effective in systems where flow rates vary—highlighting their reliability in maintaining system integrity. Additionally, the materials used for construction, such as stainless steel or PVC, can significantly affect the valve's performance under different conditions, emphasizing the importance of material selection based on the specific fluid characteristics and temperature ranges involved.

When selecting a swing check valve for your system, several key factors should be taken into account to ensure optimal flow control. Firstly, consider the valve size and pipe compatibility, as the right fit enhances efficiency and prevents leaks. Additionally, assess the flow direction and pressure conditions; choosing a valve that matches the runtime and system parameters will help maintain stability and prevent backflow.

**Tips:**

1. **Material Selection:** Choose a valve that is made from materials resistant to corrosion and wear, particularly if your application involves harsh substances. This will extend the valve's lifespan and maintain system integrity.

2. **Spring vs. No Spring:** Depending on your needs, a swing check valve with a spring can provide quicker closure speeds and help reduce water hammer, while a non-spring version is often simpler and more reliable under low-flow conditions.

3. **Maintenance Considerations:** Regularly inspect the valve for any signs of wear or debris accumulation. Implementing a routine maintenance schedule can prevent unexpected failures and prolong the overall reliability of your system.

This chart compares the flow rates of different types of swing check valves, helping to visualize which design may be more suitable for your flow control needs.

When choosing a swing check valve, it's essential to understand the different types available and their respective advantages and disadvantages. The two common variants are the traditional swing check valve and the silent check valve.

Traditional swing check valves typically feature a disc that pivots on a hinge, which helps prevent backflow. They are known for their simplicity and reliability in standard applications, making them a popular choice in various industrial settings. However, they may produce a noticeable water hammer effect when closing, which can lead to system damage over time.

In contrast, silent check valves are engineered to minimize noise and water hammer. They utilize a spring mechanism that allows for quicker closure, reducing the potential for damaging shock waves in the piping system.

This type is particularly beneficial in systems where noise reduction is a priority, such as in residential or commercial buildings. However, the added complexity of silent check valves can make them more expensive to install and maintain. By weighing these pros and cons, you can make an informed decision that aligns with your system's specific needs and operational requirements.

Installing and maintaining a swing check valve properly is crucial for ensuring optimal flow control and longevity in any system. Recent industry studies have shown that improper installation can lead to a 30% increase in flow resistance, which not only impacts efficiency but also increases energy costs significantly. When installing a swing check valve, it’s essential to ensure that it’s oriented correctly, typically in a horizontal position, to allow gravity to aid in the closure of the valve. Additionally, securing the valve with the right fasteners to prevent vibration and misalignment can prevent potential damage and failure over time.

Regular maintenance is equally important, with reports indicating that routine inspections can extend the life of a swing check valve by up to 50%. Key maintenance practices include checking for wear and tear on the disc and seat, cleaning any debris that may accumulate, and ensuring the valve operates smoothly without any signs of obstruction. Monitoring the system for abnormal noises or leaks can also help in addressing issues before they escalate. By adhering to these installation and maintenance guidelines, operators can maximize the reliability and performance of their swing check valves, leading to significant cost savings and enhanced system efficiency.

When selecting a swing check valve for your system, avoiding common mistakes is crucial to ensure optimal flow control. One prevalent error is neglecting to consider the valve's pressure rating. Using a valve with an inadequate pressure rating can lead to failures and inefficiencies, resulting in costly repairs and downtime. Always verify that the valve’s specifications align with your system’s maximum operating pressure and flow rates.

Another frequent oversight is disregarding the material compatibility. Different environments—such as corrosive fluids or high temperatures—require specific materials to prevent deterioration. Failing to choose the right material can compromise the integrity of the valve, leading to leaks or complete valve failure. Additionally, it’s essential to evaluate installation positions and orientations since some swing check valves have specific requirements for optimal performance. Choosing the right valve involves a careful assessment of these factors to prevent operational issues in the long run.

Same Day Shipping

ISO Certified Production