In the realm of industrial applications, selecting the right components is crucial for ensuring efficiency and reliability, and one component that often stands out is the swing check valve. Known for its simple yet effective design, the swing check valve plays a vital role in preventing backflow, thereby enhancing the safety and performance of fluid systems. This blog will delve into seven compelling reasons why swing check valves are an excellent choice for various industrial settings. From their cost-effectiveness to their robust performance in high-pressure environments, understanding the advantages of swing check valves can aid in optimizing your operations. Join us as we explore how these valves can transform your industrial applications and ensure seamless flow control.

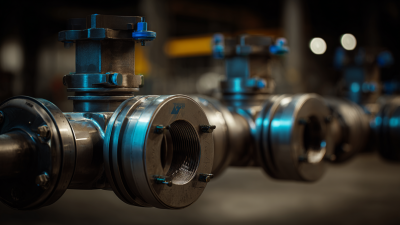

Swing check valves are an essential component in industrial systems, particularly when it comes to enhancing flow efficiency. These valves operate on a simple hinge mechanism, allowing them to open and close seamlessly based on the flow of fluid. This design minimizes resistance, resulting in an unobstructed flow path that can significantly improve overall system performance. By ensuring that the flow direction is maintained while preventing backflow, swing check valves contribute to a more efficient operation in various industrial applications, from water treatment to chemical processing.

In addition to promoting flow efficiency, swing check valves are celebrated for their durability and reliability. Constructed from robust materials, they can withstand high pressures and harsh environmental conditions, making them ideal for demanding applications. Their low maintenance requirements translate into reduced downtime and operational costs, further enhancing the efficiency of industrial systems. By choosing swing check valves, facilities can ensure a consistent and reliable flow while minimizing the risk of potential system disruptions caused by backflow.

| Reason | Benefit | Application in Industry |

|---|---|---|

| 1. Low Pressure Drop | Minimizes energy loss and improves flow efficiency. | Water treatment plants and HVAC systems. |

| 2. Simple Design | Easy to install and maintain, reducing maintenance costs. | Pipelines and gas distribution networks. |

| 3. Backflow Prevention | Protects equipment from damage due to backflow. | Chemical processing systems. |

| 4. Versatile Design | Suitable for various applications and mediums. | Food and beverage industries. |

| 5. Suitable for High Flow Rates | Allows efficient handling of large volumes of fluid. | Irrigation systems and sewage treatment. |

| 6. Durable Materials | Long lifespan, reducing replacement frequency. | Oil and gas industries. |

| 7. Cost-effective Solution | Provides long-term savings on operational costs. | Manufacturing plants and power generation. |

Swing check valves are essential components in various industrial applications, providing a reliable mechanism for preventing backflow in pipelines. Understanding the way these valves operate is crucial for maximizing their performance. The swing check valve utilizes a disc that swings on a hinge, allowing liquid to flow through in one direction while closing off when backflow occurs. This design minimizes the risk of process interruptions and enhances system efficiency, making it a smart choice for industrial setups.

*Tips: When selecting swing check valves, ensure they are made from durable materials that can withstand the specific conditions of your application. Additionally, consider the size and pressure ratings to optimize flow performance and prevent leakage.*

The effectiveness of swing check valves also hinges on proper installation and maintenance. Aligning the valve correctly within the pipeline is vital to ensure the disc functions as intended. Regular inspections can help identify any wear and tear, which in turn can preempt failures that disrupt operations.

*Tips: Implement a routine maintenance schedule to inspect and clean the valves. Utilizing visual inspections and performance monitoring can greatly improve the lifespan and effectiveness of your swing check valves.*

When it comes to selecting valves for industrial applications, swing check valves stand out for their durability and ease of maintenance. Unlike gate or ball valves, which can be more complex and prone to wear due to constant operation, swing check valves utilize a simple mechanism that allows them to close under the force of gravity and backflow, effectively minimizing the potential for damage. According to a recent industry report by TechScience, swing check valves can last up to 30% longer than their gate valve counterparts when used in applications with fluctuating pressure levels.

Moreover, maintenance for swing check valves tends to be less intensive. Their straightforward design ensures that fewer moving parts are involved, which lowers the risk of mechanical failure. A study from the Valve Manufacturers Association highlights that organizations employing swing check valves report a 20% decrease in maintenance costs over a five-year period compared to those using more complex valve types. This cost-effectiveness is especially critical in today's industrial landscape, where minimizing operational downtime and maintenance costs can provide a significant competitive edge. As industries evolve, choosing the right valve type becomes vital for optimizing performance and ensuring durability in demanding environments.

When it comes to industrial applications, swing check valves are often the preferred choice due to their distinctive design and functionality. These valves excel in scenarios where preventing backflow is crucial, such as in water treatment plants and chemical processing facilities. Their simple mechanism, which relies on a disc or flap that swings open and closed, allows for smooth flow in one direction while ensuring that any potential backflow is effectively blocked. This makes them ideal for maintaining system integrity and preventing damage or contamination.

Industries that frequently utilize swing check valves include power generation, oil and gas, and food and beverage manufacturing. In power plants, for instance, the valves help manage the flow of steam and water, ensuring that energy production processes run efficiently. In the oil and gas sector, they protect pipelines and equipment by preventing reverse flow, which can lead to dangerous leaks and spills. Similarly, in food and beverage applications, swing check valves help maintain hygiene standards by eliminating the risk of backflow, thus protecting the quality of the products being processed. Their robust design and reliability make swing check valves a cornerstone in various industrial applications, ensuring safety and efficiency.

Cost-effectiveness is a crucial factor to consider when selecting components for industrial applications, and swing check valves stand out in this respect. Unlike other valve types, swing check valves minimize backflow while maintaining low pressure drops, resulting in efficient operation. This efficiency translates to reduced energy consumption, which can lead to significant long-term savings. The design of swing check valves allows for a durable and reliable installation, ensuring that maintenance costs remain low over time.

Moreover, the longevity of swing check valves plays a vital role in their cost-effectiveness. With fewer moving parts compared to other check valves, they are less prone to wear and tear, which often leads to costly replacements. This durability is especially beneficial in high-demand industrial environments where downtime can severely impact productivity and profit margins. By investing in swing check valves, industries not only optimize their operational efficiency but also enjoy the financial benefits of reduced maintenance and replacement needs, making them a smart choice for sustainable industrial practices.

Same Day Shipping

ISO Certified Production