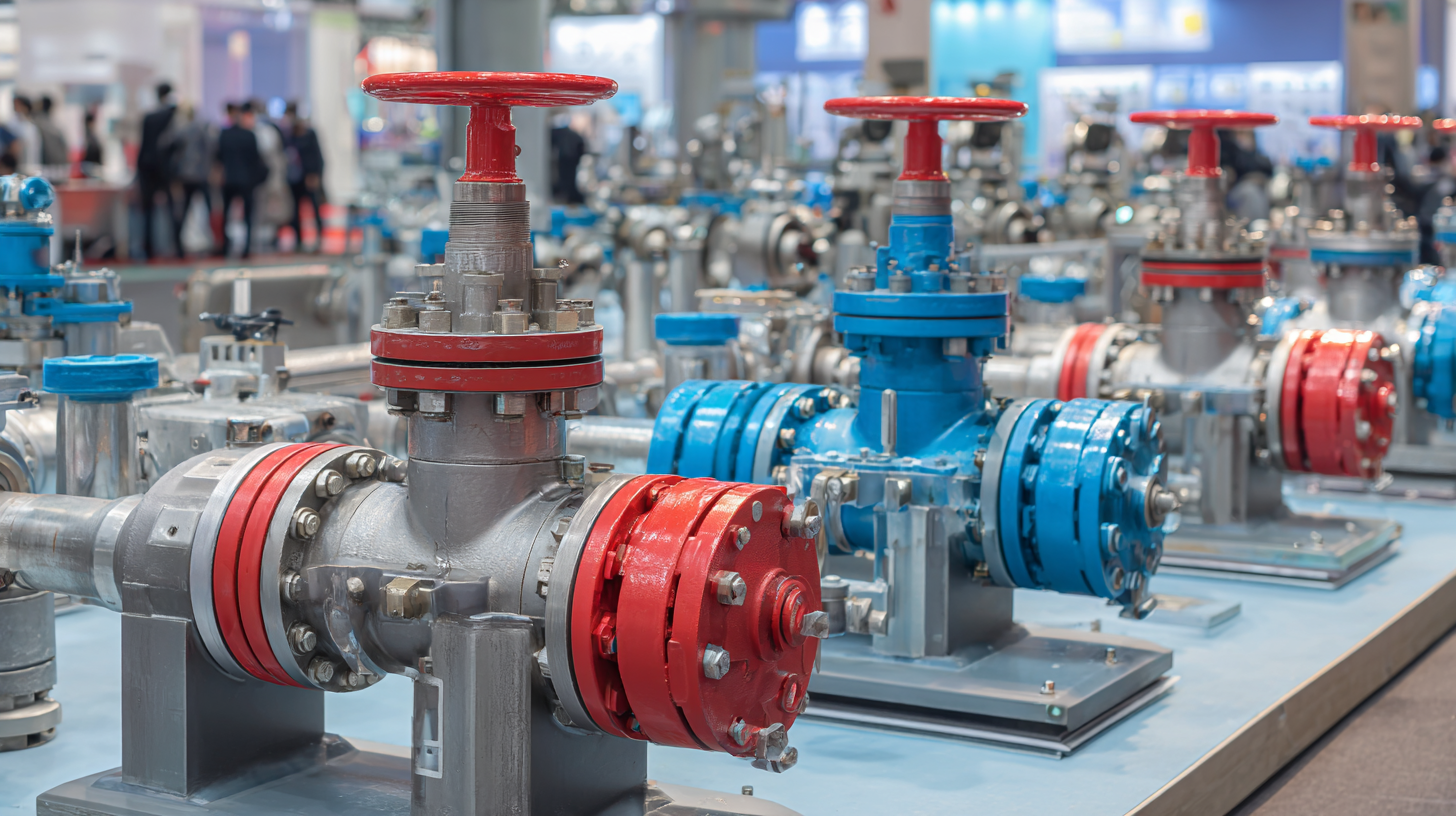

As the 138th Canton Fair approaches in 2025, the spotlight is set to shine on the latest innovations in industrial valves, a critical component in various industries including oil and gas, water treatment, and manufacturing. According to a recent report by Research and Markets, the global industrial valves market is projected to reach $85 billion by 2027, driven by the increasing demand for energy-efficient systems and automation technologies. This significant growth highlights the need for manufacturers and suppliers to showcase cutting-edge valve technologies and solutions that address efficiency, reliability, and sustainability. The Canton Fair serves as a pivotal platform for networking and knowledge exchange, providing insights into emerging trends and technological advancements that shape the future of the industrial valves sector. As key players gather to explore these innovations, the fair not only reflects current market dynamics but also sets the stage for the industry's trajectory in the years to come.

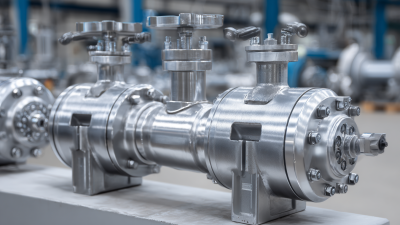

At the 138th Canton Fair in 2025, the spotlight will shine on the latest innovations in industrial valves, reflecting the industry's shift towards enhanced efficiency and sustainability. Emerging technologies such as IoT-enabled smart valves and eco-friendly materials are set to revolutionize how these critical components function. Smart valves, equipped with sensors, offer real-time data on pressure, flow rates, and potential failures, enabling predictive maintenance and reducing operational downtime.

Moreover, advances in manufacturing processes, like 3D printing, are allowing for the production of more complex and lightweight valve designs. This not only enhances performance but also contributes to sustainability by minimizing material waste. The integration of AI in valve systems is another noteworthy trend, providing improved control and automation capabilities. Visitors at the fair will have the opportunity to explore these innovations firsthand, gaining insights into how these technologies can lead to more efficient and sustainable industrial operations.

At the 138th Canton Fair in 2025, a strong emphasis on sustainability was evident in the innovations displayed in the industrial valves sector. Manufacturers demonstrated a commitment to eco-friendly practices through advanced materials and energy-efficient designs. These innovations not only minimize environmental impact but also optimize operational efficiency, aligning with global sustainability goals.

Various exhibitors showcased valves made from recycled materials, reflecting a significant shift towards circular economy principles in manufacturing. Additionally, many companies highlighted how their valve products contribute to reducing energy consumption in industrial applications. The integration of smart technologies, such as IoT-enabled monitoring systems, further complements these efforts by enabling real-time energy management and predictive maintenance, showcasing the industry's potential to drive significant sustainability advancements.

This bar chart illustrates the percentage of different sustainability trends in valve manufacturing showcased at the 138th Canton Fair 2025. The categories include Material Innovation, Energy Efficiency, Eco-friendly Production Processes, and Recycling Initiatives.

The global industrial valves market is poised for significant growth beyond 2025, driven by increasing demand across various sectors, including oil and gas, water and wastewater, and power generation. According to a recent report by Mordor Intelligence, the market is expected to reach approximately USD 108 billion by 2026, growing at a compound annual growth rate (CAGR) of around 5.1% from 2021. Emerging technologies, such as smart valves incorporated with IoT capabilities, are reshaping the landscape, offering better efficiency and real-time data monitoring.

As sustainability becomes paramount, the focus is shifting toward eco-friendly materials and energy-efficient valve designs. A report by MarketsandMarkets highlights the rising trend of automation within industrial processes, which is anticipated to enhance the demand for advanced valve systems. Furthermore, the recovery of industrial activities post-COVID-19 is likely to accelerate investments in infrastructure projects, fueling further growth in the industrial valves sector. The trends observed at events like the 138th Canton Fair highlight how innovations in valve technologies are essential for meeting the evolving needs of global industries heading into the next decade.

| Dimension | 2025 Projection | Trends |

|---|---|---|

| Market Size (USD Billion) | 45.2 | Increased demand for automation |

| Growth Rate (CAGR) | 7.5% | Integration with IoT technologies |

| Key Applications | Oil & Gas, Water Treatment | Focus on sustainability |

| Regional Growth | Asia Pacific Leading | Emerging markets supply chain growth |

| Innovative Materials | Composite and Smart Alloys | Durability and efficiency improvements |

The 138th Canton Fair in 2025 presents a unique platform for industry leaders and innovators to engage, share ideas, and foster collaborations in the realm of industrial valves. As the fair showcases the latest advancements and technologies, attendees will have numerous networking opportunities to connect with key players in the field. These connections can lead to strategic partnerships that push the boundaries of innovation and efficiency in industrial applications.

The 138th Canton Fair in 2025 presents a unique platform for industry leaders and innovators to engage, share ideas, and foster collaborations in the realm of industrial valves. As the fair showcases the latest advancements and technologies, attendees will have numerous networking opportunities to connect with key players in the field. These connections can lead to strategic partnerships that push the boundaries of innovation and efficiency in industrial applications.

In addition to formal meetings, the event will feature dedicated networking sessions that allow professionals to mingle and exchange insights in a more relaxed environment. This informal setting encourages the free flow of ideas, paving the way for new concepts and solutions to emerge. With a diverse array of participants from various sectors, the Canton Fair serves as a crossroad for creativity and discussion, ultimately benefitting the entire industrial valve industry.

At the upcoming 138th Canton Fair 2025, the spotlight will shine on innovative industrial valve solutions, showcasing how cutting-edge technologies are reshaping the industry. Among the notable trends are the integration of smart technology into valve designs, enhancing operational efficiency and remote monitoring capabilities. Companies are adopting automation and IoT connectivity to ensure precision control and maintenance, which significantly reduces downtime.

Case studies from leading manufacturers will illustrate successful implementations of these innovations. For example, a recent project demonstrated how a major chemical plant improved safety and productivity by utilizing automated valves equipped with real-time data analytics. The transition to these advanced systems not only minimized human error but also led to a remarkable 30% reduction in operational costs.

**Tips:** When exploring valve solutions, prioritize those that offer scalability and compatibility with existing systems. Investing in training for staff on these new technologies can also enhance the effectiveness of the innovations. Additionally, keep an eye on vendor support and service options, as robust after-sales support will ensure the longevity and reliability of your investment.

Same Day Shipping

ISO Certified Production