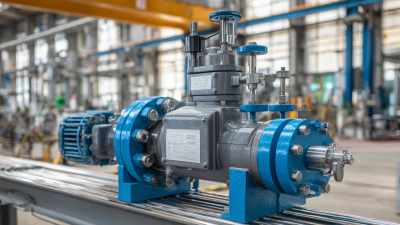

As industries continue to evolve and adapt to the demands of modern engineering and manufacturing, the significance of high pressure ball valves cannot be overstated. By 2025, we can expect to see transformative trends that not only enhance the functionality and efficiency of these critical components but also drive innovation across various sectors. The high pressure ball valve serves as a key player in managing the flow of liquids and gases under extreme conditions, making its performance and reliability paramount in applications ranging from oil and gas to chemical processing and water treatment.

In the coming years, advancements in materials, design, and automation will likely redefine the capabilities of high pressure ball valves. Emerging technologies such as smart integration and predictive maintenance tools are set to improve operational effectiveness and safety. Additionally, sustainability will influence the development of high pressure ball valves, as manufacturers seek to create more environmentally friendly solutions that reduce emissions and energy consumption. As we look forward to 2025, understanding these trends will be crucial for industry stakeholders aiming to stay ahead in the highly competitive landscape of valve technology.

The realm of high pressure ball valves is poised for significant innovations in 2025, driven by advancements in materials and design techniques. One key trend is the integration of lightweight composites that enhance durability while reducing the overall weight of the valves. These materials not only withstand extreme pressures but also improve resistance to corrosion, extending the lifespan of the products in demanding environments such as oil and gas industries.

Additionally, smart technology is increasingly playing a role in the evolution of high pressure ball valves. Manufacturers are developing valves equipped with IoT sensors that provide real-time data on performance and maintenance needs. This innovation enables predictive maintenance, minimizing downtime and operational costs. Furthermore, advancements in automation and control systems are making these valves easier to integrate into smart industrial infrastructures, allowing for enhanced efficiency and safety in fluid management processes. The combination of these innovations signifies a transformative shift towards more efficient, reliable, and intelligent high pressure ball valve designs in the near future.

This chart illustrates the anticipated growth and innovation in high pressure ball valve designs for 2025. The data represents different design features that are expected to trend significantly.

As the high-pressure ball valve industry evolves, emerging materials are playing a crucial role in enhancing performance, durability, and efficiency. A recent report from MarketsandMarkets predicts that the global ball valve market, valued at approximately $9.1 billion in 2020, is projected to reach $13.2 billion by 2025, largely driven by advancements in material science. Innovative composites and high-performance alloys are gaining traction, offering significant benefits in terms of strength, corrosion resistance, and temperature stability.

Notably, the introduction of advanced polymer materials, such as PEEK (Polyether Ether Ketone) and PTFE (Polytetrafluoroethylene), is transforming the landscape of high-pressure applications. These materials not only withstand extreme conditions but also reduce friction and wear, significantly extending the service life of ball valves. According to a study by Transparency Market Research, the adoption of such materials in valve manufacturing can enhance operational reliability by over 30%, which is a game-changer in industries where downtime is costly. As we look towards 2025, the integration of these emerging materials will undoubtedly set new performance benchmarks in the high-pressure ball valve sector.

As we look toward 2025, the market for high pressure ball valves is anticipated to thrive, fueled by an increasing demand across various sectors. According to industry reports, the acidic gas valve market is projected to reach $98.3 million in 2024 and climb to $147.09 million by 2032, marking a significant growth rate of 5.1%. This upward trend underscores the rising need for efficient and reliable high pressure solutions in industrial applications.

Moreover, the X-ray high voltage generator market is witnessing substantial expansion, primarily driven by the healthcare industry’s growing requirements. These generators play a crucial role in converting input AC power to DC and increasing the voltage to produce X-ray radiation, reflecting the technological advancements being made in medical equipment. The emphasis on precision and efficiency in these applications is likely to propel the market forward in the coming years.

**Tips:** When selecting high pressure ball valves, consider factors such as pressure ratings, material compatibility, and operational environment to ensure optimal performance. Staying updated on market trends can also guide procurement strategies effectively. Additionally, investing in high quality components may reduce long-term maintenance costs and enhance system reliability.

The integration of automation and smart technologies into valve operations is expected to significantly reshape the landscape of high-pressure ball valves by 2025. As industries strive for greater efficiency and sustainability, the use of advanced AI-driven systems will become crucial. These technologies enable real-time monitoring, predictive maintenance, and remote operations, allowing companies to minimize downtime and optimize resource management. With autonomous agents handling routine tasks, firms can focus on strategic initiatives to enhance their competitive edge in the market.

Moreover, the rise of digitalization in the energy sector aligns closely with the shifting dynamics in valve applications, particularly in the context of traditional fossil fuels transitioning to cleaner energy sources. Smart valve drivers, equipped with IoT capabilities, will facilitate better integration between legacy infrastructure and emerging renewable energy projects. This convergence of technologies not only supports cost reduction and emissions control but also drives innovation, allowing for the seamless adaptation of industrial processes to meet evolving environmental regulations and market demands.

As we approach 2025, sustainability remains a paramount consideration in the manufacturing of high pressure ball valves. The industry is witnessing a shift towards more environmentally friendly practices, driven by stringent regulations and the increasing demand for eco-conscious products. According to a recent report by MarketsandMarkets, the global ball valve market is expected to reach USD 15.3 billion by 2025, with sustainable manufacturing practices playing a critical role in this growth. Companies are investing significantly in materials that are not only durable but also recyclable, thereby reducing their carbon footprint.

To further enhance sustainability, manufacturers are adopting advanced technologies such as digital twins and predictive maintenance. These tools allow for better resource management and reduced waste during production. A survey by Deloitte indicates that 77% of manufacturers are prioritizing sustainability initiatives, integrating renewable energy sources, and optimizing supply chains to minimize environmental impact.

Tips: Consider sourcing materials that have a lower environmental impact and prioritize suppliers who are committed to sustainable practices. Engaging in continuous employee training on sustainability can also foster a culture of eco-awareness within your organization. By aligning with these trends, you can not only enhance your product's appeal but also contribute positively to the planet.

Same Day Shipping

ISO Certified Production