The global actuated ball valve market is projected to witness significant growth, with an estimated CAGR of 6.5% from 2020 to 2025, according to a report by MarketsandMarkets. As industries increasingly prioritize efficiency and reliability in fluid control systems, the demand for high-quality actuated ball valves is on the rise. These valves are essential components in various applications, including oil and gas, water treatment, and chemical processing.

When it comes to actuated ball valves, the role of quality manufacturers cannot be overstated. Actuated ball valves are critical components in fluid control systems across various industries, and their performance directly impacts operational efficiency and safety. A recent industry report by MarketsandMarkets highlights that the global valve market is projected to reach $86.3 billion by 2027, with an increasing demand for high-quality actuated valves in the oil and gas, chemical processing, and water treatment sectors. This demand emphasizes the importance of selecting manufacturers known for their stringent quality control processes and innovative engineering practices.

Quality manufacturers not only ensure compliance with industry standards but also provide valves that operate reliably under challenging conditions. According to a study published by the American Society of Mechanical Engineers (ASME), nearly 30% of valve failures can be attributed to poor manufacturing processes. By choosing manufacturers with a proven track record, buyers can mitigate risks such as leakage, operational downtime, and increased maintenance costs. Moreover, leveraging manufacturers that invest in advanced technologies, such as IoT for predictive maintenance, can enhance the overall performance and lifespan of actuated ball valves, ensuring long-term value and reliability.

This chart illustrates the importance of selecting quality manufacturers for actuated ball valves based on various criteria such as Quality Assurance, Customer Reviews, Technical Support, and Delivery Time.

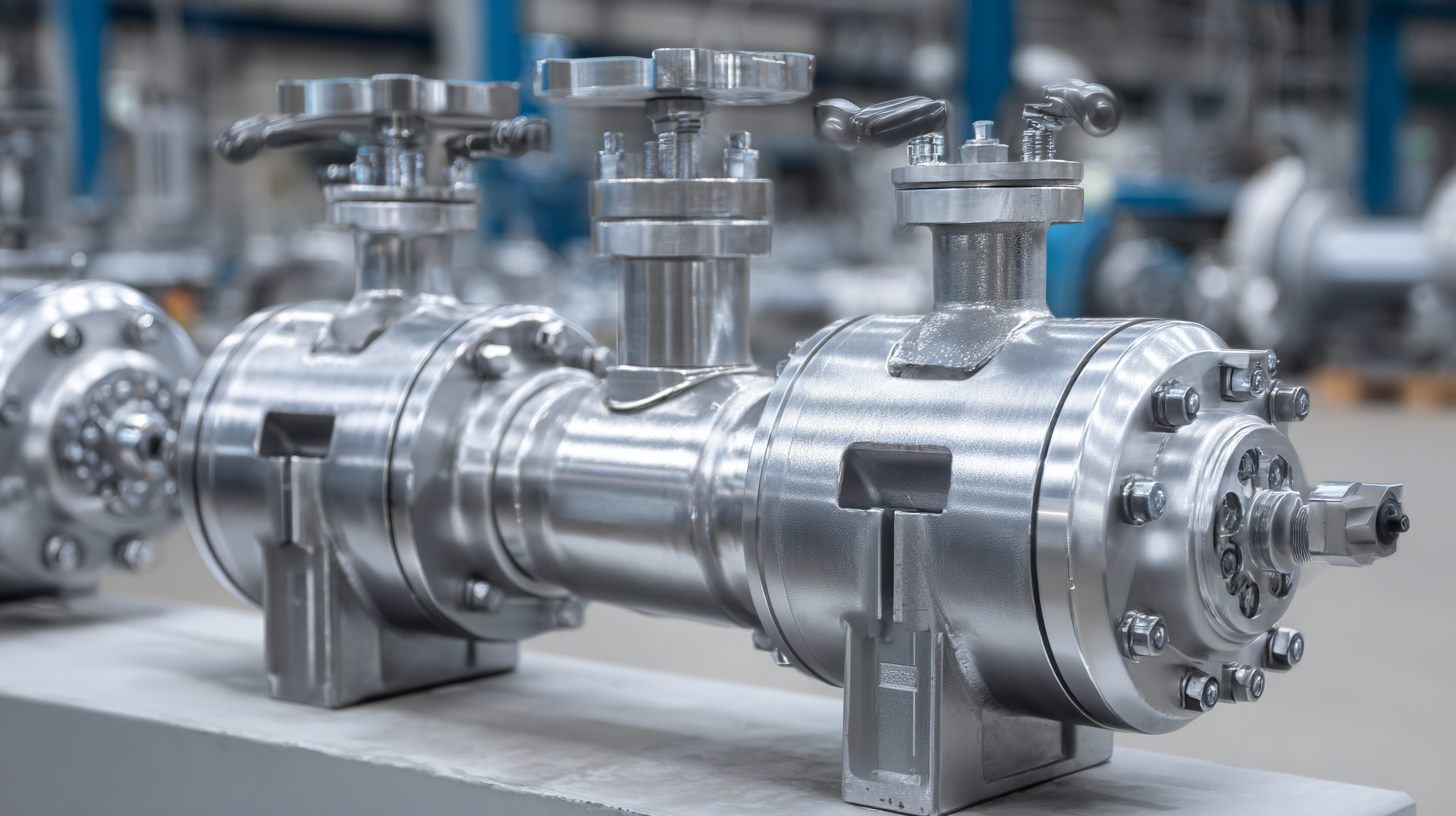

When selecting a manufacturer for high-quality actuated ball valves, several key features play a pivotal role in ensuring you partner with the right company. First and foremost, assess the manufacturer’s industry experience and expertise. A company with a long-standing history in the field is likely to understand the intricacies of valve technology and can provide better product performance and reliability. Additionally, it’s crucial to evaluate the manufacturer’s quality assurance processes. Look for certifications such as ISO 9001, which indicate a commitment to maintaining stringent quality standards throughout production.

Another essential feature to consider is the range of materials and customization options offered by the manufacturer. Top-notch actuated ball valve manufacturers typically provide a variety of materials, such as stainless steel, brass, and various plastics, catering to different applications and environments. Moreover, check if the manufacturer can accommodate custom specifications to meet unique operational requirements. This flexibility not only enhances performance but also ensures that the valves can handle specific pressures, temperatures, and corrosive substances effectively. By focusing on these key characteristics, you can make an informed decision and select a manufacturer that aligns with your needs.

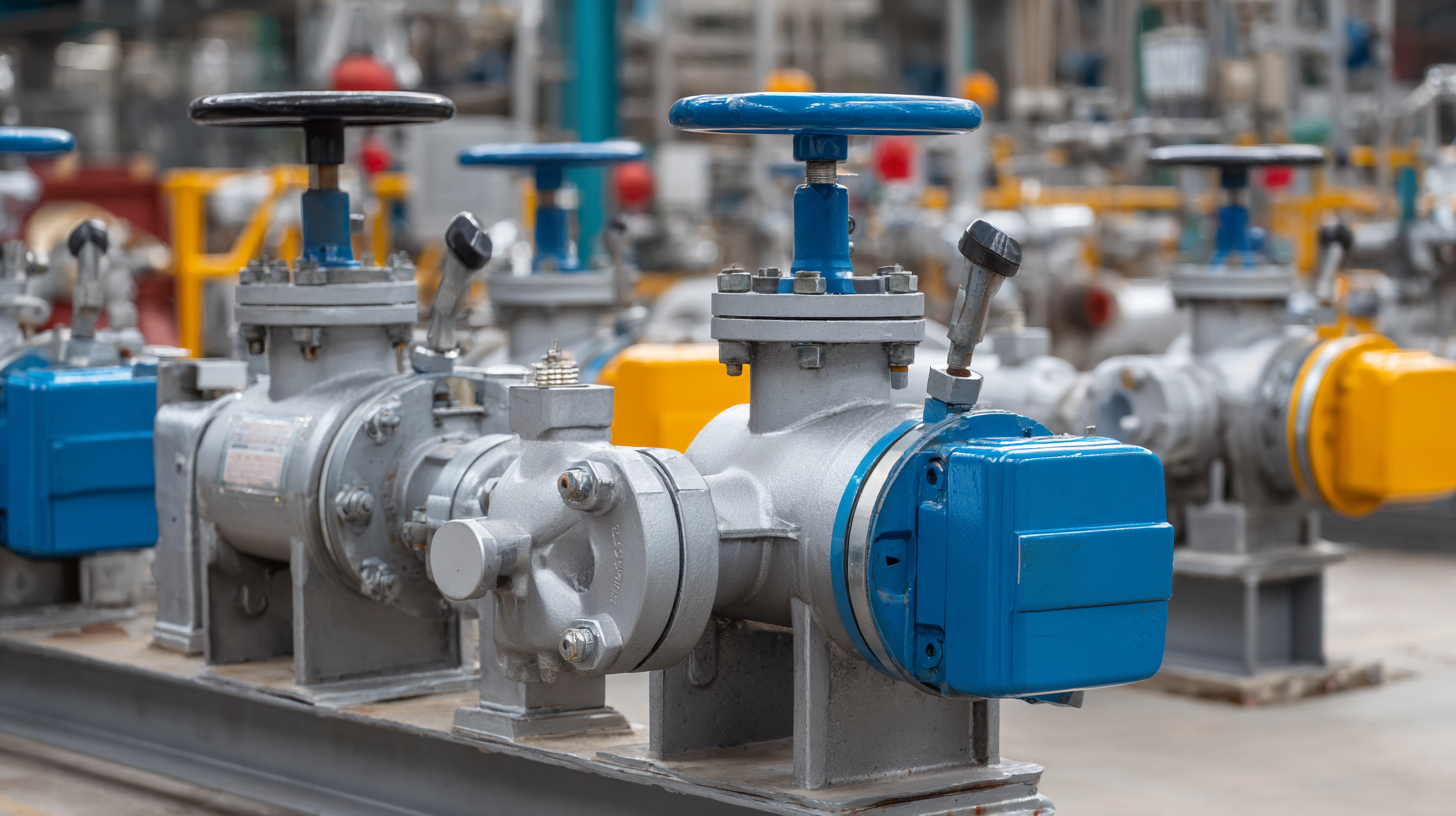

When selecting quality manufacturers for actuated ball valves, evaluating their reputation and industry experience is crucial. A reputable manufacturer often reflects their commitment to quality and compliance with industry standards. According to a report by MarketsandMarkets, the global valve market was valued at approximately $70.24 billion in 2020 and is projected to reach $92.76 billion by 2027, indicating a growing demand for reliable manufacturers. Companies with a strong track record often have higher customer satisfaction rates, which can be verified through industry reviews and testimonials.

When assessing manufacturers, consider their years in the industry. Established companies tend to have more comprehensive experience in addressing technical challenges and can better navigate regulatory requirements. Furthermore, it's beneficial to examine certifications such as ISO 9001, which indicates a manufacturer's adherence to quality management systems. Suppliers with extensive industry experience typically offer superior products that meet or exceed market expectations.

**Tips:** Always verify the manufacturer's references and ask for case studies demonstrating their previous work. Networking with industry professionals can provide insights into a manufacturer's reputation. Finally, consider manufacturers who participate in industry associations, as they are often more committed to ongoing development and standards adherence.

When selecting a manufacturer for your actuated ball valves, assessing customer support and after-sales services is crucial. A reliable manufacturer should offer comprehensive customer support, ensuring that clients can easily reach out with inquiries or concerns. Look for manufacturers with multiple contact methods—such as phone, email, and live chat—along with timely response times. This accessibility not only reflects the manufacturer’s commitment to customer service but also helps minimize operational downtime when issues arise.

In addition to pre-sale support, after-sales services play a significant role in maintaining a long-term relationship with the manufacturer. Quality manufacturers often provide installation assistance, regular maintenance, and troubleshooting support. It’s beneficial to inquire about warranty options and the availability of spare parts, as these factors can significantly impact the longevity and efficiency of your valves. By prioritizing customer support and robust after-sales services, you can ensure that you're choosing a manufacturer not just for a single purchase but for a partnership that supports your operational needs over time.

| Manufacturer Location | Customer Support Availability | Response Time (Hours) | Warranty Period (Years) | Technical Support Availability | After-Sales Services Offered |

|---|---|---|---|---|---|

| USA | 24/7 | 1 | 5 | Email and Phone | Installation Guidance, Maintenance Training |

| Germany | Business Hours | 4 | 3 | On-site and Remote | Spare Parts Supply, Repair Services |

| China | Working Hours | 8 | 2 | Online Support | Maintenance Contracts, Parts Return Policy |

| Italy | Business Hours | 12 | 4 | Phone and Email | User Manuals, Customer Training |

| Japan | 24/7 | 2 | 6 | On-site | Technical Consultation, Part Updates |

When selecting a manufacturer for actuated ball valves, one of the most critical aspects to consider is the balance between cost and quality. According to a report from the Valve Manufacturers Association, the average price reduction of 10-15% in valve components can often lead to a significant decline in performance and lifespan. For instance, lower-quality materials might save costs upfront but could lead to increased maintenance expenses and downtime, impacting overall project budgets.

Furthermore, a study by MarketsandMarkets suggests that investing in high-quality valves can enhance operational efficiency by up to 25%. This investment not only ensures reliability but also minimizes the risk of failures that can halt production lines. Therefore, while the temptation might be to go for the cheapest manufacturer, it is essential to consider the total cost of ownership. This includes potential service interruptions and repair costs, which can far exceed initial savings when quality is compromised. Ultimately, achieving the right balance hinges on a comprehensive evaluation of both immediate expenses and long-term value.

Same Day Shipping

ISO Certified Production