In modern fluid control systems, the spring check valve plays a crucial role in maintaining efficiency and safety across various applications. According to a report by Global Industry Analysts, the global market for check valves is anticipated to reach approximately $3.5 billion by 2026, driven by the increasing demand for reliable fluid management in industries such as oil and gas, water treatment, and chemical processing.

The unique functionality of the spring check valve allows for one-way flow, preventing backflow and ensuring systems operate effectively. By utilizing a spring mechanism, these valves provide enhanced performance compared to conventional models, particularly in scenarios where quick response times and durability are essential. As industries strive for greater operational reliability, understanding the intricate workings of spring check valves becomes increasingly important for engineers and maintenance professionals alike.

Spring check valves play a crucial role in various modern applications by ensuring unidirectional fluid flow, thereby preventing backflow in pipelines. These valves utilize a spring mechanism that exerts pressure on the valve disc, allowing it to close tightly against the seat when the flow reverses. According to a recent industry report by MarketsandMarkets, the global check valve market is projected to reach $4.3 billion by 2026, signifying the growing importance of effective fluid control systems in industries such as oil and gas, water treatment, and chemical processing.

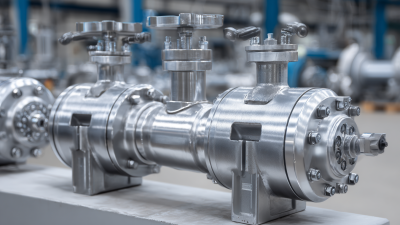

Key features of spring check valves include their compact design, ease of installation, and reliability under fluctuating pressure conditions. They are typically made from high-quality materials such as stainless steel or plastic, allowing for resistance against corrosion and wear. The ability of spring check valves to operate silently contributes to their widespread use, as indicated by the Fluid Power Journal, which highlights that silent operation remains a primary selection criterion for many engineers.

Tips for selecting the right spring check valve include assessing the specific application requirements, such as flow rates and pressure ranges. Additionally, it’s essential to consider the compatibility of materials to prevent chemical degradation. Regular maintenance and inspection can also extend the lifespan of these valves, ensuring optimal performance in critical applications.

This bar chart illustrates the key features of spring check valves in various applications. Each feature is represented along with its significance rating from a scale of 1 to 10.

Spring check valves play a crucial role in fluid systems by ensuring unidirectional flow and preventing backflow. These devices operate based on a simple yet effective principle: a spring-loaded disc inside the valve allows fluid to flow in one direction while closing off when reverse flow occurs. This action is primarily driven by the differences in pressure and the force exerted by the spring.

When the fluid pressure exceeds the spring tension, the disc lifts and permits flow; when the pressure drops or reverses, the spring forces the disc back to its seat, creating a seal and stopping any backward movement of the fluid.

Tip: When selecting a spring check valve for your application, consider the pressure rating and size carefully. Choosing a valve that matches your system's specifications will ensure optimal performance and longevity.

The efficiency of a spring check valve can also be influenced by factors such as fluid viscosity and flow rates. High-viscosity fluids may require valves with softer springs to minimize the risk of flow resistance. Additionally, it is essential to orient the valve correctly in the system to maximize its efficacy.

Tip: Regular maintenance is key to keeping spring check valves functioning properly. Periodically inspect the valve for wear or buildup and replace it as necessary to avoid failures in your fluid system.

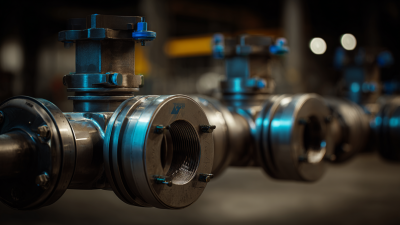

Spring check valves play a critical role in various industrial applications due to their unique ability to prevent backflow in piping systems. These valves are commonly used in water treatment facilities, pools, and irrigation systems, where maintaining the correct flow direction is essential for efficiency and safety. Their design allows for quick response to pressure changes, ensuring that fluids flow only in the desired direction, thus protecting pumps and other equipment from potential damage caused by reverse flow.

Spring check valves play a critical role in various industrial applications due to their unique ability to prevent backflow in piping systems. These valves are commonly used in water treatment facilities, pools, and irrigation systems, where maintaining the correct flow direction is essential for efficiency and safety. Their design allows for quick response to pressure changes, ensuring that fluids flow only in the desired direction, thus protecting pumps and other equipment from potential damage caused by reverse flow.

In manufacturing environments, spring check valves are vital for processes involving hazardous or sensitive materials. For instance, in the chemical industry, these valves are employed to prevent the backflow of corrosive fluids, safeguarding the integrity of the production line. Similarly, in food and beverage applications, they help maintain hygiene by ensuring that contaminants from the distribution system do not enter clean lines. The versatility and reliability of spring check valves make them indispensable across a variety of sectors, highlighting their importance in maintaining operational efficiency and safety.

Spring check valves play a crucial role in various modern applications by providing a reliable one-way flow mechanism, which prevents backflow in piping systems. Their functionality is essential in industries ranging from water treatment to petroleum, where maintaining system integrity is paramount. According to a report from the Global Market Insights, the demand for check valves is expected to grow by over 5% annually due to increasing infrastructure projects and stringent safety regulations. This rise in demand highlights the advantages of spring check valves, including their compact design and ease of installation, contributing to lower maintenance costs and improved operational efficiency.

Spring check valves play a crucial role in various modern applications by providing a reliable one-way flow mechanism, which prevents backflow in piping systems. Their functionality is essential in industries ranging from water treatment to petroleum, where maintaining system integrity is paramount. According to a report from the Global Market Insights, the demand for check valves is expected to grow by over 5% annually due to increasing infrastructure projects and stringent safety regulations. This rise in demand highlights the advantages of spring check valves, including their compact design and ease of installation, contributing to lower maintenance costs and improved operational efficiency.

However, evaluating the performance of spring check valves requires a careful assessment of their disadvantages as well. One significant drawback is their susceptibility to failure under certain conditions, such as rapid pressure fluctuations or exposure to corrosive materials. A study published in the Journal of Hydraulic Engineering emphasizes that while spring check valves offer quick response times, they may struggle to maintain functionality over prolonged use in harsh environments. Moreover, depending on the application, manufacturers must consider the specific characteristics of the fluid and system pressure, as improper selection can lead to inefficiencies or system failures. Consequently, understanding both the advantages and limitations of spring check valves is critical for ensuring their effective use in modern applications.

Spring check valves play a crucial role in modern applications by ensuring the proper flow of fluids and preventing backflow. To maintain their efficiency and prolong their lifespan, regular maintenance is essential. One key tip is to routinely inspect for any signs of wear or damage, such as cracks or corrosion. If you identify any issues, replacing the valve promptly can prevent further complications.

Another important aspect of maintenance is lubrication. Keeping the moving parts well-lubricated not only reduces friction but also enhances the overall operational durability of the valve. Consider using a light machine oil to facilitate smooth motion and prevent seizure. Additionally, it’s beneficial to periodically clean the valve to remove any debris or buildup that could interfere with its functionality.

Lastly, when it comes to installation, ensure that the valve is correctly oriented and that all fittings are secure. Improper installation can lead to premature failure, negating any maintenance efforts. By following these simple tips, you can maximize the longevity and reliability of your spring check valves in various applications.

Same Day Shipping

ISO Certified Production