In the world of industrial applications, selecting the right components is crucial for ensuring optimal performance and durability. Among these components, titan valves have gained popularity due to their strength, corrosion resistance, and reliability under various conditions. However, with a plethora of options available in the market, making the right choice can be overwhelming. This blog aims to provide you with seven essential tips to help you navigate the selection process for titan valves tailored to your specific industrial needs. Whether you are dealing with high-pressure systems, corrosive environments, or specific flow requirements, understanding the key factors that influence the performance and longevity of these valves will empower you to make informed decisions. Join us as we explore the critical aspects of choosing the best titan valves to enhance your operations and ensure seamless productivity.

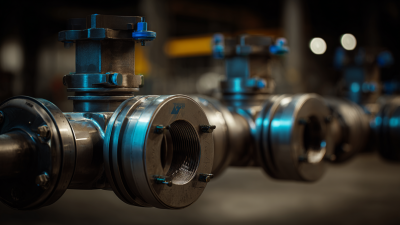

When it comes to industrial applications, selecting the right Titan valves is crucial to ensuring optimal performance and safety. Titan valves come in a variety of types, each designed to serve specific functions within industrial systems. Whether you need ball valves for quick shut-off, gate valves for throttling flow, or butterfly valves for lightweight applications, understanding the distinctions among these types is essential.

Ball valves are highly regarded for their durability and reliability, making them ideal for applications that require fast opening and closing. On the other hand, gate valves are better suited for applications where minimal flow resistance is needed, as they provide a straight-through flow path. Conversely, butterfly valves are favored for their compact design and ease of installation, particularly in large pipelines. By aligning your specific industrial needs with the right type of Titan valve, you can enhance operational efficiency and reduce the risk of costly downtime. Understanding these differences will empower you to make informed decisions that align with your project's requirements.

When selecting Titan valves for industrial applications, evaluating material compatibility is crucial to ensuring optimal performance and longevity. The environment in which these valves operate can significantly impact their effectiveness. Using the right materials not only enhances performance but also reduces the ecological footprint. Recent findings highlight that certain materials, such as ceramics, tend to have a less detrimental environmental impact compared to traditional metallic options. This is particularly relevant when considering the lifetime costs and sustainability of the materials involved.

In the context of Titan valves, it's essential to assess how the materials used in their construction interact with the specific elements they will be exposed to. Factors such as temperature, pressure, and chemical exposure must be thoroughly evaluated. By opting for materials that minimize ecological damage while still meeting the demands of the industrial setting, businesses can invest wisely in valves that are both effective and environmentally friendly.

This proactive approach not only addresses immediate operational needs but also aligns with growing sustainability goals in various industries.

When selecting Titan valves for industrial applications, understanding key performance metrics is crucial. Two primary factors to consider are pressure ratings and flow characteristics. Pressure ratings indicate the maximum pressure a valve can withstand, which directly affects its functionality and safety in various processes. High-pressure capabilities are essential for industries dealing with gases and liquids under extreme conditions.

Flow characteristics, on the other hand, refer to how fluids maneuver through the valve. Different valve designs influence flow patterns and efficiency. It's beneficial to conduct a thorough evaluation of flow models relevant to specific valve types, as this can reveal insights into optimizing performance. Additionally, modern advancements in valve technology, such as automated evaluations of biochemical plant KPIs, highlight the importance of utilizing data-driven approaches to assess operational efficiency.

Flow characteristics, on the other hand, refer to how fluids maneuver through the valve. Different valve designs influence flow patterns and efficiency. It's beneficial to conduct a thorough evaluation of flow models relevant to specific valve types, as this can reveal insights into optimizing performance. Additionally, modern advancements in valve technology, such as automated evaluations of biochemical plant KPIs, highlight the importance of utilizing data-driven approaches to assess operational efficiency.

As you narrow down your choices, always ensure to measure both pressure ratings and flow characteristics against your specific industrial needs. This way, you can select Titan valves that not only meet but exceed your expectations in performance and reliability.

When selecting Titan valves for your industrial applications, understanding certification standards is crucial for ensuring compliance and reliability. Certification standards, such as those set by the American Society for Testing and Materials (ASTM) and the American National Standards Institute (ANSI), provide a benchmark for quality and performance. Valves that meet these standards are rigorously tested to withstand the demands of various industrial environments, making them essential for maintaining operational integrity.

In addition to performance, certification also speaks to the safety and regulatory compliance of the valves you choose. Industries such as oil and gas, pharmaceuticals, and food processing must adhere to strict regulations to protect workers and the environment. By prioritizing valves that meet established certification standards, companies can mitigate risks associated with failures or non-compliance, ensuring that both operational and safety protocols are satisfied.

Thus, understanding and verifying the certification of Titan valves can significantly contribute to the success of your industrial projects.

When selecting Titan valves for industrial applications, understanding the total cost of ownership (TCO) is crucial for long-term financial viability. While the initial purchase price of valves can vary, this upfront cost often pales in comparison to the cumulative expenses over the product's lifespan. Analyzing factors such as maintenance, energy efficiency, and potential downtime can reveal a clearer picture of how quality Titan valves contribute to savings over time.

Investing in high-quality Titan valves might involve a higher initial expenditure, but these products are designed for durability and reliability. They typically require less frequent replacements and maintenance, reducing labor costs and minimizing unexpected shutdowns. By choosing valves that meet the specific demands of your industry, you can optimize performance and significantly lower operating costs. The long-term benefits of using Titan valves far outweigh the initial costs, making them an intelligent choice for any industrial operation focused on efficiency and sustainability in their processes.

| Valve Type | Material | Size (inches) | Pressure Rating (psi) | Initial Cost ($) | Expected Lifespan (years) | Total Cost of Ownership ($) |

|---|---|---|---|---|---|---|

| Ball Valve | Stainless Steel | 2 | 150 | 100 | 20 | 500 |

| Gate Valve | Brass | 3 | 200 | 120 | 15 | 800 |

| Check Valve | PVC | 1.5 | 75 | 40 | 10 | 200 |

| Butterfly Valve | Ductile Iron | 4 | 300 | 150 | 25 | 600 |

| Globe Valve | Carbon Steel | 2.5 | 150 | 130 | 20 | 650 |

Same Day Shipping

ISO Certified Production