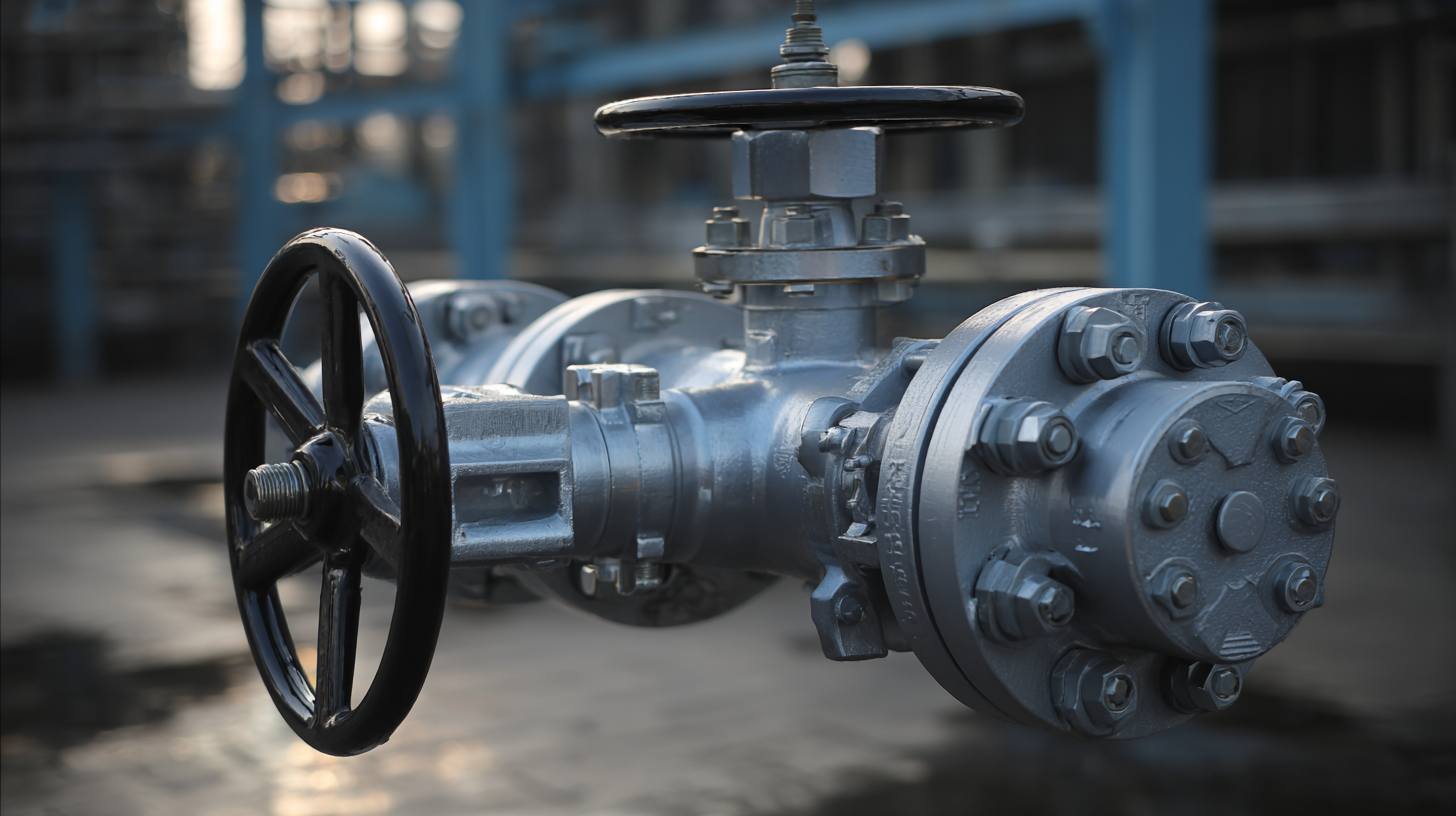

In today's industrial landscape, the selection of the right equipment plays a vital role in optimizing operations and ensuring efficiency. Among the essential components used in various sectors, the slide gate valve stands out due to its unique ability to control the flow of bulk solids and liquids with precision. According to a recent market report by the Global Valves Market Analysis, the slide gate valve segment is projected to grow significantly, driven by advancements in automation and the rising demand for enhanced process control in industries such as mining, wastewater treatment, and food processing. Choosing the appropriate slide gate valve can lead to increased reliability, decreased downtime, and improved overall productivity. As operations become increasingly complex, understanding the key factors in selecting the right valve is crucial for maintaining a competitive edge. In this blog, we will explore five essential tips to help you make informed decisions when choosing a slide gate valve for your operations.

When selecting the right slide gate valve for your operations, it is crucial to understand their basic functions and applications. Slide gate valves are primarily used in industries for controlling the flow of bulk materials and fluids. Their design allows for minimal leakage and pressure drop, which is essential in ensuring operational efficiency. According to recent industry reports, proper valve selection can increase system reliability by up to 30%, emphasizing the importance of making informed choices.

One key aspect to consider is the material of construction for slide gate valves. Common materials such as carbon steel, stainless steel, and plastic composites each offer different advantages based on the operational environment. For instance, a report highlighted that valves made from stainless steel could withstand corrosive substances more effectively, thus leading to reduced maintenance costs and extended service life in demanding applications. Understanding these properties can save time and resources in the long run, making it vital to align the valve specifications with the operational requirements.

When selecting a slide gate valve for your operations, several key factors should be carefully considered to ensure optimal performance and reliability. First and foremost, consider the material of the valve. Depending on the substances being transported, you may need a valve that can withstand corrosive materials or high temperatures. Popular materials include stainless steel and ductile iron, each offering distinct advantages based on the application.

Another critical factor is the valve design and size. It's essential to match the valve size to the flow rate and system requirements. An incorrectly sized valve can lead to inefficient operations or damage to the system. Additionally, assess the actuator mechanism, as this influences the ease of operation and maintenance. Hydraulic, pneumatic, and electric actuators each have their pros and cons, and your choice should align with both operational needs and ease of access for maintenance. By taking these factors into account, you can ensure that your slide gate valve meets the demands of your specific application effectively.

When selecting the appropriate slide gate valve for your operations, material compatibility is a critical factor that cannot be overlooked. The material of the valve must be suited for the specific application it will be used in, taking into consideration the properties of the media being handled. Whether it’s corrosive fluids, high-temperature gases, or abrasive solids, the wrong material choice can lead to premature wear, leaks, and ultimately, system failure. Common materials like stainless steel, carbon steel, and various polymers each offer different advantages and limitations. Therefore, a thorough understanding of the media's chemical composition, temperature range, and pressure conditions is essential.

Moreover, evaluating the environmental conditions where the valve will operate is equally important. Factors such as exposure to moisture, extreme temperatures, or aggressive chemicals can significantly influence material performance. For instance, although a valve made from aluminum may be lightweight and cost-effective, it may not withstand erosive environments as effectively as a more robust alloy. By carefully assessing both the operational demands and environmental conditions, organizations can ensure they select a slide gate valve that not only functions optimally but also enhances the overall efficiency and longevity of their operations.

When selecting the right slide gate valve for your operations, understanding size and flow requirements is crucial. Proper sizing ensures optimal performance and efficiency. In industries such as microfluidics, where flow rates can be very low, specialized designs like Tesla valves have emerged. Research indicates that these valves can maintain high efficiency even at low flow rates, making them suitable for applications that demand precise control over fluid movement. A numerical analysis of flow characteristics reveals that optimizing the valve's dimensions significantly affects its performance.

Furthermore, a multistage optimization method has been developed to analyze forward and reverse flow in Tesla valves based on varying width-to-narrow ratios. This indicates that even slight adjustments in valve design can lead to significant improvements in flow characteristics, thereby enhancing operational efficiency. By applying computational fluid dynamics (CFD) in the evaluation process, engineers can accurately assess the performance of different valve sizes and designs under varying operational conditions. This data-driven approach is essential for ensuring that the selected slide gate valve meets both the size and flow requirements essential for your specific applications.

When it comes to maintaining a slide gate valve, proactive strategies can significantly extend its lifespan and ensure operational efficiency. According to a study conducted by the Valve Manufacturers Association (VMA), regular maintenance can increase equipment longevity by up to 30%. This requires a scheduled inspection routine that includes checking seals, actuators, and the valve body for any signs of wear or corrosion.

In addition to routine inspections, the choice of materials plays a vital role in the durability of slide gate valves. Industry reports indicate that using high-quality alloys and coatings can enhance resistance to abrasive and corrosive environments, thereby reducing the frequency of necessary replacements. Implementing a robust lubrication schedule also contributes to reducing friction and wear, further supporting the valve's performance. By investing in maintenance and choosing the right materials, operations can ensure that their slide gate valves remain reliable, resulting in fewer downtimes and lower overall costs in the long run.

| Tip Number | Tip Title | Detailed Description | Expected Lifespan | Maintenance Frequency |

|---|---|---|---|---|

| 1 | Material Selection | Choose materials that resist corrosion and wear based on your operational environment. | 10-15 years | Annually |

| 2 | Size and Pressure Rating | Ensure the valve’s size and pressure rating match the specifications of your system. | 15 years | Biannually |

| 3 | Seal Type | Select appropriate seals that are compatible with the media being controlled. | 5-10 years | Quarterly |

| 4 | Actuation Method | Choose the correct actuation method (manual, pneumatic, or electric) based on ease of use and access. | 10-20 years | Annually |

| 5 | Supplier Support | Evaluate the support and maintenance services offered by the supplier. | Depends on usage | As needed |

Same Day Shipping

ISO Certified Production