When selecting the right ball check valve for your project, it is crucial to understand its significance in ensuring the proper flow of media within your piping system. Ball check valves are designed to prevent backflow, allowing fluid to flow in one direction while effectively blocking any reverse flow. This essential function not only protects equipment from potential damage but also enhances the system's overall efficiency. As such, choosing the appropriate ball check valve is a key task that requires careful consideration of various factors.

This guide provides ten essential tips to help you navigate the complexities of selecting the right ball check valve for your specific needs. From understanding the materials used in construction to recognizing the importance of size and pressure ratings, each tip is aimed at equipping you with the knowledge needed for making an informed decision. By keeping these factors in mind, you can ensure that the ball check valve you choose will not only meet the demands of your project but also provide reliable performance and longevity in your piping applications.

Ball check valves are crucial components in various fluid systems, playing a key role in preventing backflow and ensuring the efficient flow of liquids. These valves operate using a spherical ball that sits in a valve seat, allowing fluid to flow in one direction while automatically sealing off when backflow is detected. According to a report by MarketsandMarkets, the global valve market is projected to reach USD 90.2 billion by 2026, driven by the increasing demand for effective fluid control solutions across industries such as water treatment, oil and gas, and chemicals.

In terms of applications, ball check valves are utilized in numerous settings, including wastewater management, HVAC systems, and food and beverage processing. Their versatility stems from their ability to handle various media, including corrosive fluids and slurries. A study by Research And Markets highlights that the rise in industrial automation and the adoption of modern technologies are elevating the demand for reliable valve systems. By selecting the right ball check valve tailored to the specific needs of a project, engineers can enhance system efficiency, reduce maintenance costs, and ensure compliance with safety standards.

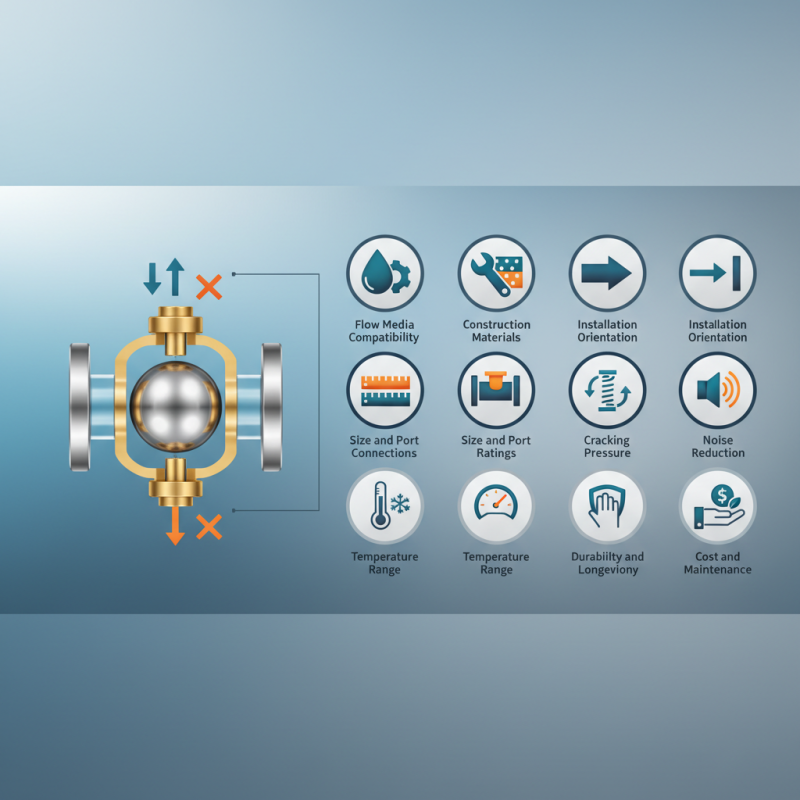

When selecting a ball check valve for your project, several key factors warrant consideration to ensure optimal performance and suitability for your application's requirements. Firstly, understand the fluid characteristics that the valve will encounter, including temperature, pressure, and the type of fluid—whether it's a liquid or gas. The material of the valve is crucial since it must resist corrosion and wear based on the nature of the fluid, as well as withstand the operating conditions it will be subjected to. Common materials include stainless steel, brass, and various plastics, each offering specific mechanical properties that can affect longevity and reliability.

Another significant aspect to evaluate is the valve size and connection type, which should match the piping system to ensure proper flow and minimize pressure drops. Incorrect sizing can lead to inefficiencies or failures in the system. Additionally, consider the installation requirements, as some ball check valves may necessitate specific orientations or clearances for effective operation. Finally, pay attention to certifications and standards that the valve meets, as these can be indicative of quality and safety assurance needed for compliance in various industries. By carefully assessing these factors, you can make an informed decision that aligns with the needs of your project.

| Tip Number | Key Factor | Description | Considerations |

|---|---|---|---|

| 1 | Material | Choose the correct material for your fluid compatibility. | Consider corrosiveness and temperature of the media. |

| 2 | Pressure Rating | Ensure the valve can handle your system's pressure. | Check the maximum working pressure and safety factor. |

| 3 | Size | Select an appropriate size for flow requirements. | Consider pipe diameter and flow rate. |

| 4 | End Connections | Choose the right type of end connection for installation. | Consider flanged, threaded, or welded options. |

| 5 | Sealing Mechanism | Look for reliable sealing to prevent leaks. | Evaluate seat materials and designs. |

| 6 | Flow Direction | Choose a valve that allows flow in the correct direction. | Ensure the valve design accommodates your system layout. |

| 7 | Temperature Range | Select a valve suited for the temperature of your fluid. | Check both ambient and operational temperature limits. |

| 8 | Maintenance Accessibility | Ensure easy access for maintenance and inspections. | Plan for space and accessibility around the valve. |

| 9 | Regulatory Compliance | Confirm that your valve complies with industry standards. | Research relevant local and international regulations. |

| 10 | Cost-Effectiveness | Balance quality with budget constraints. | Consider long-term operational costs and reliability. |

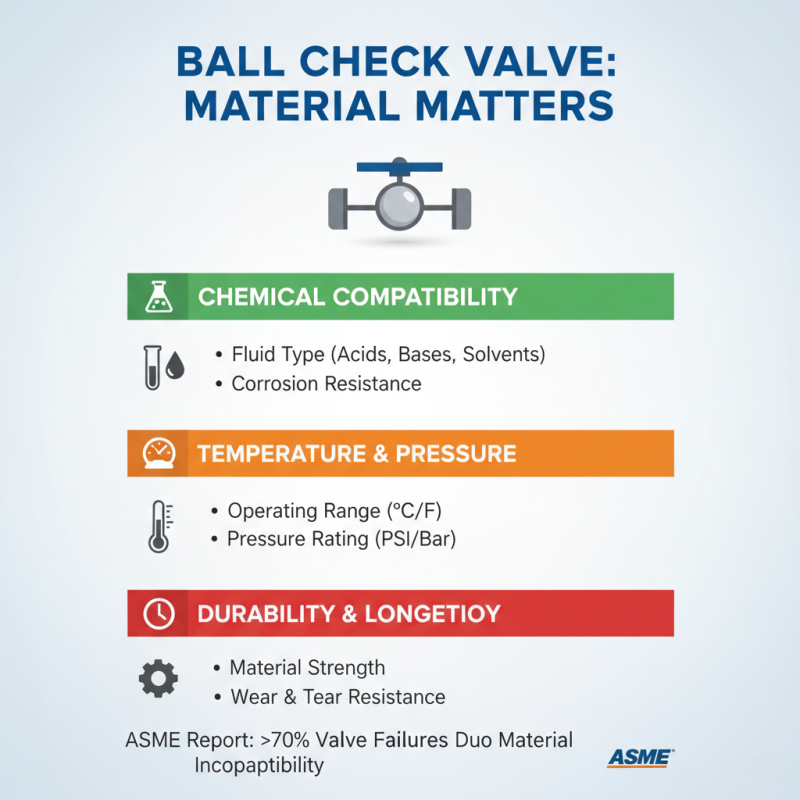

When selecting a ball check valve for your project, material compatibility is a critical factor that cannot be overlooked. Different materials offer varying levels of resistance to chemicals, temperature, and pressure, which directly impacts the valve's performance and longevity. According to a report by the American Society of Mechanical Engineers (ASME), over 70% of valve failures are attributed to material incompatibility, emphasizing the importance of making informed choices.

For applications that involve corrosive substances, materials such as stainless steel or plastic composites are often recommended due to their superior resistance to a range of chemicals. The 2021 “Materials Performance” report indicated that valves made from high-grade polymers exhibit a lifespan increase of over 50% in harsh environments compared to traditional materials. Conversely, metals like brass or bronze may be suitable for water or air applications, but they can suffer from corrosion when exposed to aggressive fluids. Therefore, it’s essential to assess the specific conditions of your project, including the media being transported, the operational pressures, and temperature ranges.

In industries such as wastewater treatment and chemical processing, the right material choice not only enhances the efficiency of the ball check valve but also reduces maintenance costs significantly. Research from the Valves and Actuators Technical Committee highlighted that the initial investment in higher-quality materials can lead to a return on investment (ROI) of over 20% through decreased downtime and repairs. Understanding the nuances of material compatibility will ensure that your ball check valve functions optimally for its intended purpose, delivering reliability and safety throughout its operational life.

When selecting a ball check valve, proper sizing is crucial for achieving optimal performance in your system. The size of the valve should match the flow requirements of your application, ensuring it can handle the expected volume without causing excessive pressure drops or flow restrictions. To determine the appropriate size, start by calculating the flow rate needed for your project, which can be influenced by factors such as pipeline diameter, fluid characteristics, and the specific installation conditions.

Additionally, consider the pressure rating and the type of fluids the valve will handle. Ball check valves operate effectively by allowing fluid to flow in one direction while preventing backflow, so selecting a size that can withstand operational pressures is essential. A well-sized valve not only enhances the efficiency of the system but also minimizes wear and tear, potentially extending the service life of both the valve and adjacent components. Proper installation and alignment are also vital in ensuring that the check valve operates seamlessly within the pipeline system.

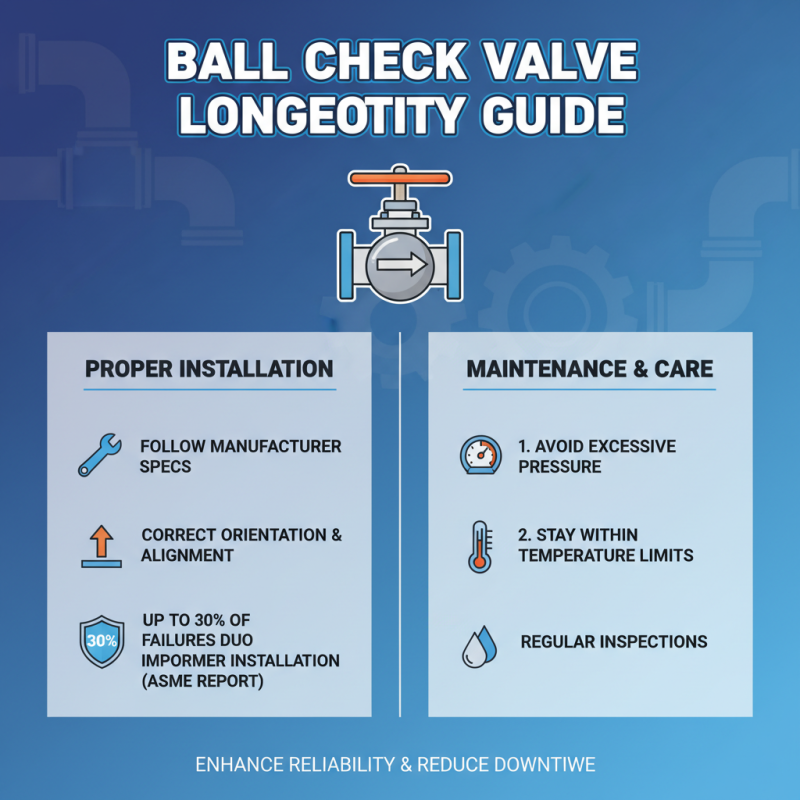

When choosing the right ball check valve for your project, it is essential to pay close attention to installation and maintenance practices that can significantly enhance the longevity of the valve. Proper installation is critical; it is essential to adhere to the manufacturer’s specifications regarding orientation and alignment. According to a report by the American Society of Mechanical Engineers, improper installation accounts for up to 30% of valve failures, emphasizing the need for precision and expertise during the installation phase. Additionally, ensuring that the valve is not subjected to excessive pressure or temperature beyond its specified limits can prevent early degradation.

Regular maintenance also plays a vital role in extending the life of check valves. Implementing periodic inspections can help identify issues such as wear and tear or build-up of debris, which can impede valve function. The Valve Manufacturers Association outlines that preventive maintenance can reduce operational costs by up to 25% over the lifecycle of the valve. Moreover, keeping a log of valve performance can help in recognizing patterns that may lead to premature failure, allowing for timely interventions. Adopting these practices can result in increased reliability and reduced downtime for projects reliant on check valves, ultimately contributing to both efficiency and cost savings.

Same Day Shipping

ISO Certified Production