In today's competitive industrial landscape, selecting the right components is crucial for operational efficiency and reliability. One such critical component is the titan check valve, which plays a significant role in controlling fluid flow and preventing backflow in various applications. According to a recent market research report by Grand View Research, the global check valve market is projected to reach $5.6 billion by 2025, driven by the increasing demand from sectors such as oil and gas, water and wastewater management, and chemical processing. This growth underscores the importance of sourcing high-quality valves, particularly from reputable manufacturers in China, known for their advanced production techniques and stringent quality control measures. By opting for the best titan check valve from China's quality manufacturing partner, businesses can ensure enhanced performance, durability, and ultimately, a competitive edge in their operations.

In modern industrial applications, titan check valves play a crucial role in ensuring operational efficiency and safety. These valves are designed to prevent backflow, allowing fluids to flow in only one direction. This functionality is essential in various sectors, including oil and gas, water treatment, and chemical processing. By investing in high-quality titan check valves from reputable manufacturers, businesses can enhance their systems' reliability and longevity.

**Tip:** When selecting a titan check valve, consider the specific pressure and temperature requirements of your application. Proper specifications will help avoid potential damage and facilitate smooth operations.

Another significant benefit of titan check valves is their ability to handle corrosive materials, which is a common scenario in industrial environments. The durable nature of titanium ensures that these valves maintain their integrity over time, even in challenging conditions. This aspect not only promotes safety but also reduces maintenance costs.

**Tip:** Regularly inspect your titan check valves for signs of wear or damage. Timely maintenance can prevent unforeseen failures and ensure that your operations run without interruptions.

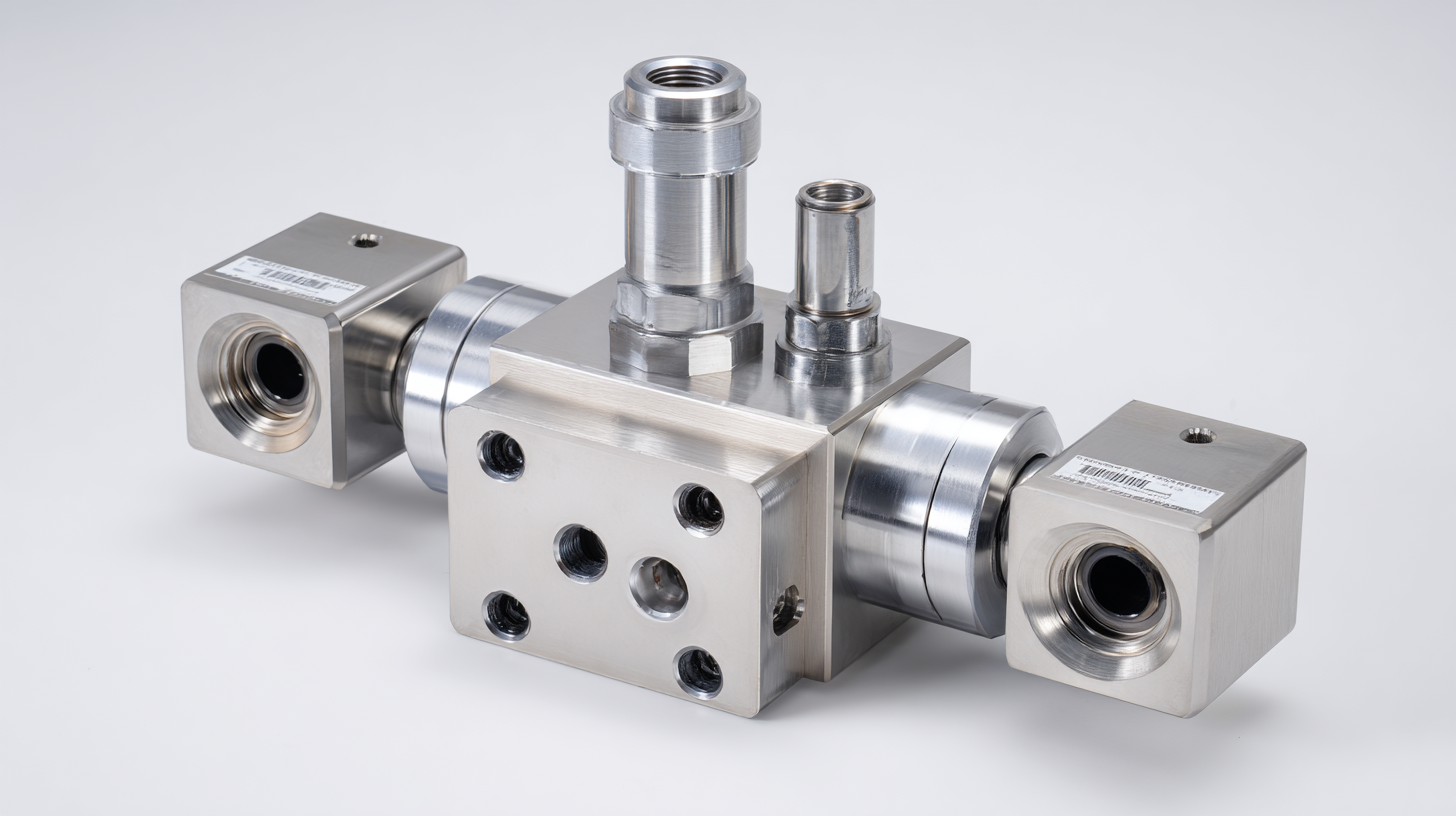

When sourcing Titan check valves from Chinese manufacturers, it's crucial to understand the key features that determine their quality and reliability.

First and foremost, look for valves made from high-grade materials such as stainless steel or brass.

These materials not only enhance durability but also ensure the valves can withstand extreme pressure and temperature variations.

Additionally, check for certifications like ISO or CE, which indicate compliance with international quality standards.

Another essential aspect is the design of the valve itself.

A well-engineered check valve will ensure smooth flow while preventing backflow effectively.

Consider features like a simple and efficient internal mechanism, which can significantly affect performance and maintenance needs.

Moreover, you should prioritize manufacturers who offer customizable options, allowing you to tailor the valves to your specific applications.

Tip: Always request samples before committing to bulk orders.

Testing a prototype will give you insights into its performance and compatibility with your system.

Additionally, inquire about the manufacturer's after-sales support, as this can be indicative of their commitment to customer satisfaction and product quality.

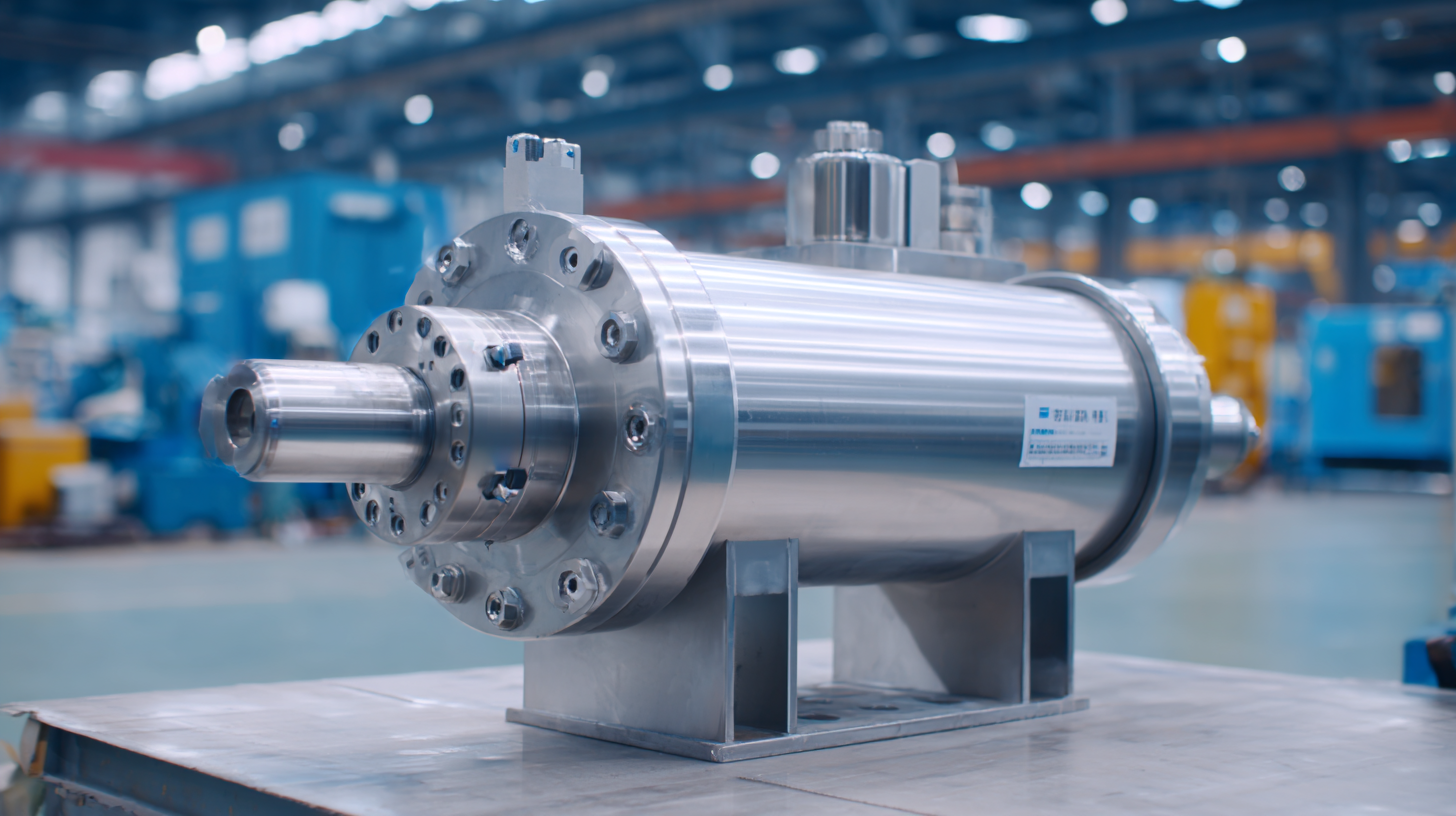

Quality manufacturing plays a crucial role in the durability of check valves, especially in demanding industrial applications. According to a report by Research and Markets, the global valve market is projected to reach $100 billion by 2026, driven by the increasing demand for efficient flow control in various sectors. In this context, the manufacturing quality of components such as Titan check valves directly influences their performance and lifespan. High-quality materials and advanced manufacturing processes ensure that these valves can withstand extreme pressures and corrosive environments, ultimately leading to increased operational efficiency and reduced maintenance costs.

Moreover, a study published by the American Society of Mechanical Engineers highlights that the failure rates of poorly manufactured valves can be up to 30% higher than those produced under stringent quality control standards. This underscores the importance of partnering with a reliable manufacturer. By investing in high-quality Titan check valves, businesses not only ensure compliance with safety regulations but also enhance their operational reliability. Leveraging advanced manufacturing technologies, such as CNC machining and automated assembly, further ensures that every valve meets rigorous quality standards, thereby maximizing durability and minimizing downtime in industrial processes.

| Material | Max Pressure (MPa) | Temperature Range (°C) | Size (Inches) | Durability (Cycles) |

|---|---|---|---|---|

| Stainless Steel | 1.6 | -50 to 220 | 1 | 500,000 |

| Cast Iron | 1.0 | 0 to 120 | 2 | 300,000 |

| PVC | 0.6 | -10 to 60 | 1.5 | 200,000 |

| Brass | 1.0 | -20 to 160 | 1 | 250,000 |

| Ductile Iron | 1.6 | -30 to 120 | 2.5 | 400,000 |

Innovative technologies are revolutionizing the design of check valves, ensuring enhanced efficiency and reliability across various industrial applications. Modern materials like high-performance polymers and advanced alloys have emerged, allowing for better resistance to corrosion, wear, and high temperatures. These innovations not only prolong the lifespan of the valves but also reduce maintenance costs, making them a smart investment for businesses aiming to streamline operations.

Moreover, the integration of digital technologies, such as IoT sensors and smart automation, is enabling real-time monitoring and data analysis in check valve systems. This means that businesses can gain valuable insights into performance metrics, predict potential failures, and optimize maintenance schedules. The ability to monitor valve performance remotely leads to improved decision-making and increased operational efficiency, further solidifying the importance of cutting-edge technology in this sector. As Chinese manufacturers continue to lead the way in quality production and innovative designs, businesses can leverage these advancements to elevate their operations and maintain a competitive edge in the market.

This chart illustrates the performance metrics of advanced check valve technologies. Key factors such as Material Quality, Pressure Rating, Flow Efficiency, Corrosion Resistance, and Lifecycle Cost have profound implications on the durability and performance of check valves.

As we approach 2025, businesses aiming for growth in the competitive global market must carefully evaluate their manufacturing partners. The global foodservice market is projected to reach a staggering $402.76 billion, demonstrating a significant opportunity for companies that can leverage effective supply chain strategies. Finding a quality manufacturing partner is not merely about reducing costs; it's also about enhancing product quality and ensuring sustainability. A strategic partnership with a reliable manufacturer can propel a business's ability to innovate and respond to market trends.

In addition to the foodservice sector, the demand for advanced manufacturing technologies is skyrocketing. The smart manufacturing market is expected to grow from $394.35 billion in 2025 to $998.99 billion by 2032, showcasing an annual growth rate of 14.2%. Companies need to tap into this trend by aligning with manufacturers that prioritize technological advancements and quality control. By partnering with top-tier manufacturers, businesses can enhance their operational efficiencies, leading to improved customer satisfaction and a stronger competitive edge in various sectors, including refrigeration and defense.

Same Day Shipping

ISO Certified Production