Choosing the right ball check valve for your application can be challenging. Industry expert Mark Johnson states, "Selecting the right ball check valve is crucial for efficiency and safety." This highlights the importance of making informed choices.

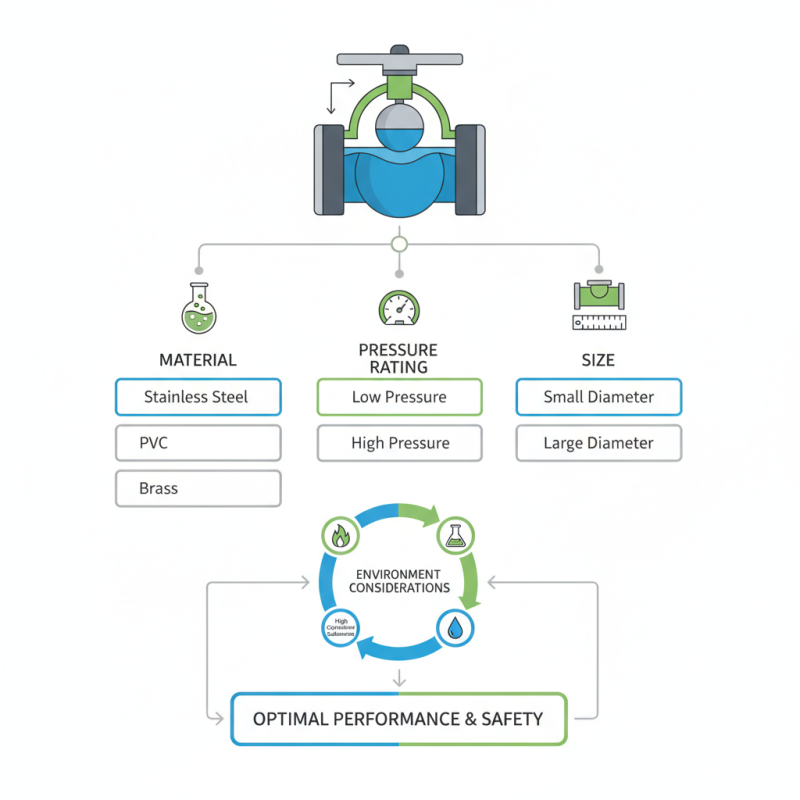

When selecting a ball check valve, consider your specific needs. The materials of the valve, pressure ratings, and size are key factors. A mismatch can lead to failures or leaks. Think about the environment the valve will operate in, too. Will it face high temperatures or corrosive substances?

It's easy to overlook small details. These details can significantly impact performance. Evaluating options may feel overwhelming. However, understanding the purpose of the ball check valve simplifies the process. Each application carries unique requirements. Therefore, reflection on these factors will lead to better choices in the long run.

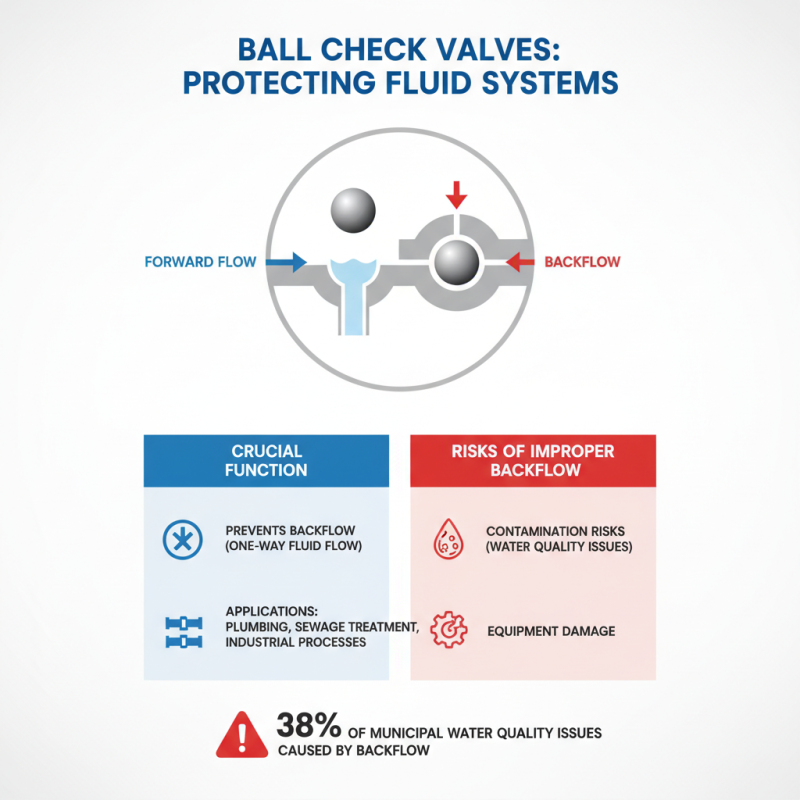

Ball check valves serve a crucial function in various applications. They allow fluid to flow in only one direction, preventing backflow. This feature is vital in plumbing systems, sewage treatment, and industrial processes. According to a recent industry report, improper backflow can lead to significant contamination risks and equipment damage. In fact, backflow incidents can cause nearly 38% of water quality issues in municipal systems.

Understanding the benefits of ball check valves can streamline operations. These valves are often preferred for their simple design. They have fewer moving parts, which reduces maintenance needs. Research indicates that these valves can increase system efficiency by up to 25%. Their ability to handle high pressure and temperature ranges makes them versatile. However, not all ball check valves are equal. Selecting the wrong valve could lead to leaks or failures.

In practical terms, consider the materials and sizes available. While brass and PVC are common, each choice has its drawbacks. For instance, PVC is lightweight but can degrade under UV exposure. Some applications may not prioritize UV resistance, but it's essential to consider longevity. Regular inspections of installed valves are also critical. Neglecting maintenance can result in performance declines or even total failures.

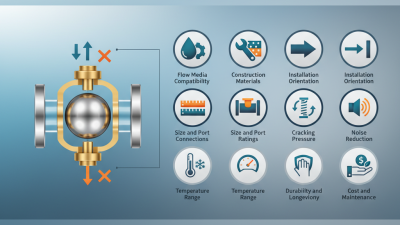

When selecting a ball check valve, it’s crucial to consider several key factors. Flow direction is essential; ensure that the valve allows for reverse flow prevention. According to industry reports, improper flow direction can lead to significant operational issues. Size and diameter matter too. A mismatch can cause pressure drops, affecting system efficiency.

Material selection is another vital aspect. The valve's body must withstand the specific fluid type and temperature. For instance, corrosive substances require robust materials to prevent degradation. Studies show that choosing the wrong material can reduce valve lifespan by up to 30%. Furthermore, pressure rating cannot be overlooked; it must align with your system's demands.

Installation orientation can also impact performance. Some valves are not effective if installed incorrectly. As per data from industry analysts, nearly 15% of valve failures stem from improper installations. Take the time to evaluate these factors. They significantly influence reliability and longevity in systems requiring ball check valves.

Choosing the right ball check valve is crucial for any application. There are several types available. Each type serves different purposes. A simple way to start is by understanding the working principle of these valves.

One common type is the spring-loaded ball check valve. It relies on a spring to keep the ball in position. This design is effective for low-pressure applications. It ensures a tight seal when needed. On the other hand, the gravity-operated ball check valve uses gravity to function. It’s best for vertical installations. Issues can arise if the valve isn’t positioned correctly.

Consider also the material of the valve. Options include brass, stainless steel, and plastic. Each material has its strengths and weaknesses. For example, plastic may be cost-effective, but it can wear out quickly. Conversely, stainless steel lasts longer but comes at a higher price. Reflect on how these factors align with your specific needs.

Choosing the right ball check valve involves careful consideration of material compatibility. A valve made from unsuitable materials can lead to failures. This can disrupt operations and cause costly downtime. According to industry reports, about 30% of valve failures are attributed to improper material selection.

For example, if a valve is used in a corrosive environment, stainless steel may not suffice. In this case, materials like polypropylene or fluoropolymers could be preferable. A survey from the Valves Manufacturers Association indicates that 27% of users experienced issues when using the wrong material in critical applications.

Temperature and pressure ratings also play a crucial role. Materials need to withstand specific operational conditions. Interestingly, nearly 40% of users report that they consider these ratings as secondary factors. This oversight can lead to unexpected leaks or valve malfunctions. Thus, it's essential to assess all factors to avoid long-term issues.

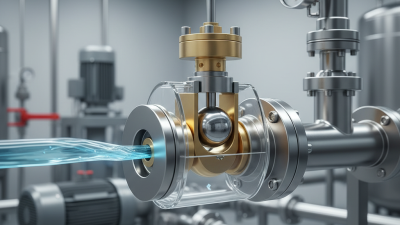

Installing ball check valves may seem straightforward, but careful attention is necessary. Proper positioning can prevent backflow and ensure efficiency. Make sure to check the orientation before installation. The valve must align correctly with the flow direction indicated. Incorrect placement could lead to leaks or failure.

Regular maintenance is crucial for optimal performance. Inspect valves periodically for wear and tear. Pay attention to any unusual noises or leaks. These could signal that the valve is not functioning properly. Cleaning is also important; debris can hinder operation. If you notice any issues, do not hesitate to replace parts. Sometimes, the best solution is to reevaluate your system entirely. Keeping a maintenance log can help track performance over time. Consider potential improvements based on your observations. Continuing to learn from each experience will enhance your valve management skills.

| Parameter | Description | Material | Pressure Rating (psi) | Temperature Range (°F) |

|---|---|---|---|---|

| Diameter | The size of the valve opening | PVC | 150 | 32 to 140 |

| Type | Type of ball check valve | Stainless Steel | 300 | -20 to 250 |

| Connection Style | How the valve connects to pipes | Bronze | 200 | 32 to 180 |

| Seal Material | Material used for sealing | EPDM | 250 | -40 to 212 |

| Maintenance | Recommended frequency for service | N/A | N/A | N/A |

Same Day Shipping

ISO Certified Production