Choosing the right stainless steel woven wire mesh is crucial for various industries. This material offers strength and durability that is often unmatched. According to a report by Smith Market Analytics, the global market for stainless steel wire mesh is projected to grow at a CAGR of 5.2% by 2025. This growth emphasizes the increasing demand across many sectors, including food and beverage, pharmaceuticals, and construction.

Industry expert Dr. Sarah Chen states, “Selecting the right type of stainless steel woven wire mesh is essential for maximizing performance and longevity.” This insight resonates throughout the industry, highlighting the importance of material choice. Different mesh types serve various applications; thus, understanding these differences is vital for optimal use.

Yet, many businesses still struggle with this selection process. They often overlook important factors such as wire diameter, mesh count, and corrosion resistance. These elements can drastically impact performance and lifespan. Therefore, knowing what to look for in stainless steel woven wire mesh is crucial for making informed decisions.

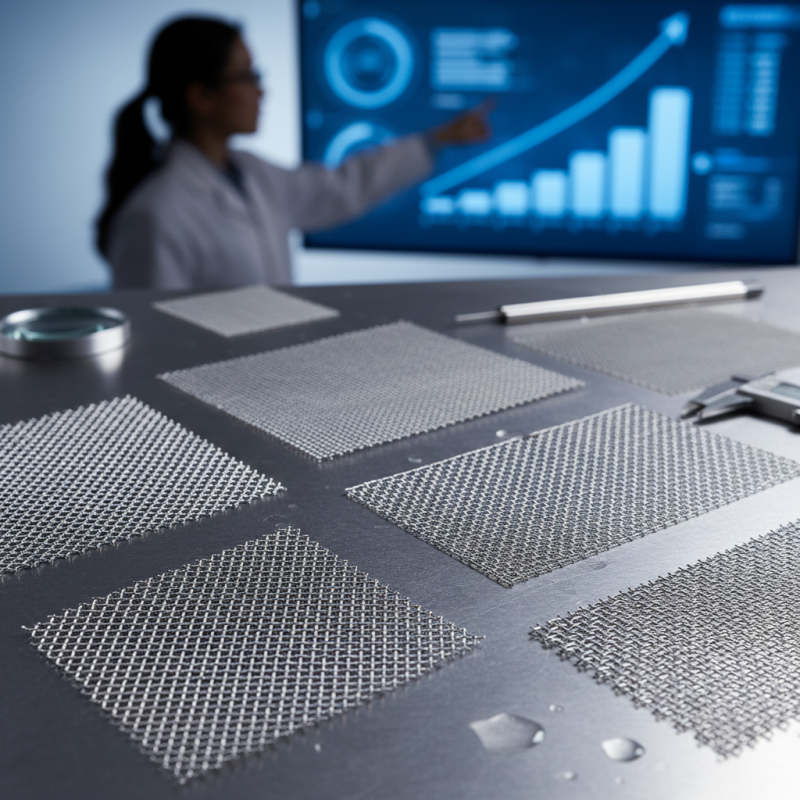

Selecting the right stainless steel woven wire mesh involves several key factors. The application is crucial. Different environments require specific mesh types. If it's for food processing, a finer mesh might be needed. For industrial uses, a sturdier design could be better. Consider the wire diameter. Thicker wires can provide more strength, while thinner wires offer better flexibility. The choice greatly impacts the overall durability of the mesh.

Mesh opening size is another important aspect. Smaller openings filter finer particles but may restrict airflow. Large openings allow for better fluid movement but do not trap small debris. It's essential to find a balance based on your specific needs. Additionally, the weave pattern can greatly influence performance. Plain weave is common, but twill weave offers better strength and stability under tension.

Lastly, take into account the material grade. Certain alloys resist corrosion better than others. This can significantly extend the lifespan of the mesh. Yet, not all projects require high-grade materials. Budget constraints and project lifespans should guide your choice. Often, the perfect mesh might not exist, leading to compromises. Careful consideration will help avoid issues in the long run.

| Mesh Type | Wire Diameter (mm) | Opening Size (mm) | Applications | Mesh Count | Material Grade |

|---|---|---|---|---|---|

| Plain Weave | 0.5 | 1.0 | Filtration, sieving | 20 | 304 |

| Twill Weave | 0.7 | 2.0 | Heavy-duty applications | 30 | 316 |

| Dutch Weave | 0.6 | 0.5 | Precision filtration | 40 | 430 |

| Reverse Dutch Weave | 0.8 | 0.75 | High pressure filtration | 50 | 304 |

When selecting stainless steel woven wire mesh, understanding grade variations is crucial. Stainless steel is primarily categorized by grades, such as 304 and 316. Each grade has specific properties affecting durability. For instance, 304 is resistant to corrosion in mild conditions. However, it may not withstand harsh environments as well as 316. The addition of molybdenum in 316 increases its resistance to chloride, making it ideal for marine applications.

Tips: Always consider the environment where the mesh will be used. If exposed to saltwater or chemicals, opt for higher grades like 316. This choice may seem costly initially but can save money on replacements or maintenance in the long run.

Another critical factor is the wire diameter and weave type. A thicker wire offers greater strength, but flexibility may be sacrificed. Not every project requires super-strong mesh. Be mindful of your actual needs. Sometimes, a lighter mesh might suffice, leading to potential cost savings.

Tips: Assess the load and stress the mesh will endure. Avoid over-engineering your solution; it can lead to unnecessary expenses. Balancing functionality and budget is essential in making the right choice.

When selecting the right stainless steel woven wire mesh, mesh size and opening specifications are crucial. The size of the mesh determines the level of filtration. Smaller openings capture finer particles, while larger ones allow for better airflow and drainage. This balance is vital for different applications.

Think about your specific needs. For instance, in a food processing environment, tight mesh can prevent contamination. In construction, larger openings might be necessary for ventilation. Each situation demands careful consideration of mesh size. The wrong choice can lead to inefficiencies or even operational failures.

Not every option will suit your requirements perfectly. It's essential to test and evaluate various meshes. You might find that the specifications vary based on the source or batch quality. Assessing the material's durability is equally important. Ensuring the longevity of the stainless steel mesh can prevent unexpected replacements or repairs. Experiment and document your findings for future reference.

When choosing stainless steel woven wire mesh, environmental conditions are crucial. Different settings present unique challenges. For instance, high humidity environments can cause corrosion. Selecting mesh with proper grades can mitigate this risk. Temperatures that fluctuate significantly might also affect the performance of the wire mesh.

Applications vary widely based on these environmental factors. For outdoor use, a mesh designed for harsh climates is vital. It should resist UV rays and rust. In contrast, food processing environments demand high sanitary standards. A smooth, non-absorptive surface is key here. The choice here demands careful thought and consideration.

Consideration of specific requirements is essential. For example, decorative purposes may prioritize aesthetics over functionality. Yet, compromising on durability can lead to future issues. Look for balance. A wire mesh that suits your environment will enhance longevity and effectiveness. Reflect on how environmental factors could affect your choices. The right decision today can save complications tomorrow.

Choosing the right stainless steel woven wire mesh involves careful consideration of costs and quality. Many buyers face the challenge of balancing their budget with the need for durable and high-quality materials. A higher price tag often reflects better resistance to corrosion and wear. However, it's crucial to assess whether the added features justify the extra expense. A mid-range option might serve well for general purposes without breaking the bank.

When evaluating cost-effectiveness, think about the intended application. Heavy-duty tasks may require a more robust mesh. In contrast, lighter applications might not benefit from premium features. Take the time to compare different suppliers and products. Look out for customer reviews. Sometimes, lower-priced alternatives perform just as well. Yet, be cautious; cheap options might falter sooner than expected.

A critical reflection is necessary when evaluating your choices. Are you opting for price alone? Will that mesh fulfill your requirements in the long run? The balance isn't always straightforward. You might feel tempted by a bargain, but it may lead to regret later. Understanding the specific needs of your project will guide you to the right decision. This balance of quality and budget is essential for making an informed choice.

Same Day Shipping

ISO Certified Production