Choosing the right industrial valves for your application needs is a critical decision that can significantly impact the efficiency, safety, and reliability of your operations. Industrial valves play a vital role in controlling the flow of liquids and gases in various industries, including oil and gas, water treatment, chemical processing, and manufacturing. The selection process requires a thorough understanding of the specific requirements of your application, such as pressure, temperature, flow characteristics, and the types of fluids handled.

In this guide, we will explore the key factors to consider when selecting industrial valves, including material compatibility, valve design, and performance specifications. Understanding these factors will help you identify the most suitable valve type, whether it be ball valves, gate valves, globe valves, or any other variety, ensuring that your operations remain efficient and compliant with industry standards. By making informed decisions about industrial valves, you can enhance system performance while minimizing downtime and maintenance costs, ultimately leading to greater operational success.

When selecting industrial valves, it's essential to understand the diverse types that are available in the market. Generally, industrial valves can be categorized into several types, including gate valves, globe valves, ball valves, butterfly valves, and check valves. Each type serves a specific purpose and is suited for different applications based on the medium being handled, the required flow control, and the system pressure ratings. According to a report by MarketsandMarkets, the industrial valve market is projected to reach $94.4 billion by 2028, demonstrating a significant demand for efficient and reliable valve solutions across various industries.

Gate valves are primarily used to allow or prevent the flow of liquids, providing minimal resistance when fully open, making them ideal for on/off applications. In contrast, globe valves are more suited for throttling purposes as they offer excellent flow regulation. Ball valves, known for their quick operation, are widely used for shut-off applications, while butterfly valves provide a compact solution for flow control in larger pipes. Check valves, on the other hand, play a critical role in preventing backflow, ensuring that the flow remains in one direction. The choice of valve type significantly impacts operational efficiency, safety, and maintenance costs, aligning with the specific requirements of various sectors such as oil and gas, water treatment, and chemical processing.

This chart illustrates the common applications of different types of industrial valves, helping you to choose the right valve for your specific application needs. The data reflects the popularity and typical use cases for each valve type in industrial settings.

When selecting industrial valves, evaluating material compatibility is paramount to ensure optimal performance and longevity. Different applications expose valves to varying chemical agents, temperatures, and pressures, necessitating careful consideration of the materials used in valve construction. According to the “Industrial Valve Market Outlook 2023” report by MarketsandMarkets, nearly 30% of valve failures can be traced back to material incompatibility, highlighting the need for diligent assessment during the selection process.

Corrosion resistance is a critical factor, especially in industries such as chemical processing and oil and gas. For instance, stainless steel, recognized for its durability, is often favored for its resistance to rust and corrosion when in contact with aggressive chemicals. The American Society for Testing and Materials (ASTM) outlines specific standards for various materials, enabling engineers to match valve materials with their specific application environments accurately. Data from the “Global Industrial Valves Market” report indicates that the demand for corrosion-resistant valves is projected to grow by 4.5% annually as industries continuously seek ways to mitigate operational risks and enhance equipment lifespan.

Thermal stability is another essential consideration that influences material selection. High-temperature applications may require specialized materials such as nickel alloys, which maintain strength and integrity at elevated temperatures. Research from the Journal of Materials Science reveals that selecting the right valve material can enhance operational efficiency by 20%, reducing maintenance costs and downtime considerably. By ensuring material compatibility, industries can safeguard their operations against costly failures and achieve better sustainability outcomes.

When selecting industrial valves, understanding the pressure and temperature requirements of your application is crucial.

Each industrial environment presents unique challenges, and the right valve must withstand the specific conditions it will face. High-pressure systems may require valves made of robust materials that can endure significant force without compromising integrity. Conversely, low-pressure applications may allow for more flexibility in materials but still necessitate careful consideration of potential pressure fluctuations.

Temperature also plays a vital role in valve selection. Standard materials may not perform adequately if exposed to extreme heat or cold. It’s essential to assess the maximum and minimum temperatures the valve will encounter. For instance, valve seals and elastomers can deteriorate rapidly in high-heat environments, leading to leaks and operational failures. When evaluating the thermal aspects, always consult technical data sheets to ensure compatibility with your system's thermal profile.

Tips:

1. Consider using pressure relief valves for systems prone to pressure spikes to enhance safety and prevent damage.

2. Always perform a thorough analysis of the thermal management aspects of your system to select valves that not only match operational needs but also ensure longevity and reliability.

When selecting industrial valves, understanding the actuation methods is crucial for ensuring optimal functionality and efficiency in your application. Actuation methods refer to the mechanism that opens and closes the valve, which can significantly influence the performance and reliability of fluid control systems. Common actuation methods include manual, pneumatic, hydraulic, and electric actuation. Each method has its advantages and is suitable for different operational environments.

Tip: Consider the specific requirements of your application, such as the operating pressure, temperature ranges, and the type of medium being controlled. This will help you determine the most suitable actuation method. For instance, pneumatic actuators are often preferred in high-speed operations, while hydraulic actuators are ideal for applications requiring high force in a compact design.

Additionally, the choice of actuation method should factor in automation needs. Electric actuators provide enhanced control and can be easily integrated into automated systems, while manual actuators might suffice for simpler operations. Tip: Evaluate the potential need for future upgrades or expansions in your system; selecting a versatile actuation method can save costs and time in the long run. By carefully assessing your application’s demands, you can choose the right actuation method that aligns with operational requirements and budget considerations.

| Valve Type | Actuation Method | Application | Pressure Rating (PSI) | Material |

|---|---|---|---|---|

| Ball Valve | Electric Actuator | Water Treatment | 150 | Stainless Steel |

| Gate Valve | Manual | Oil & Gas | 300 | Carbon Steel |

| Butterfly Valve | Pneumatic Actuator | HVAC Systems | 150 | PVC |

| Check Valve | Gravity | Plumbing | 200 | Brass |

| Solenoid Valve | Electrical | Automation | 100 | Nylon |

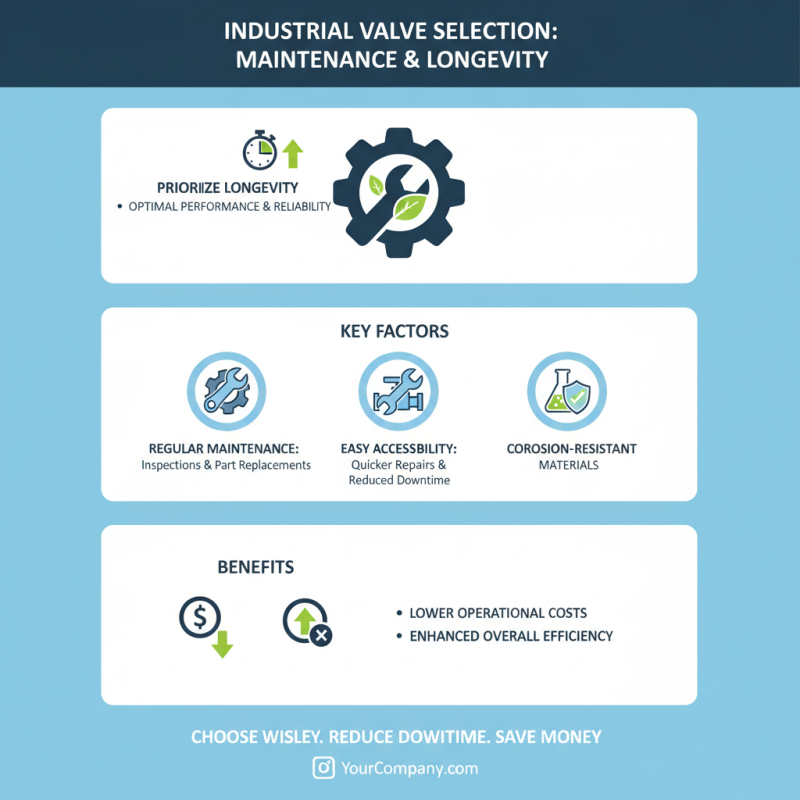

When selecting industrial valves, it is essential to prioritize maintenance and longevity to ensure optimal performance and reliability in your application. Regular maintenance routines, including inspections and part replacements, can significantly extend the lifespan of valves. Choosing valves designed with easy accessibility for servicing can facilitate quicker repairs and reduce downtime. Additionally, selecting materials that resist corrosion and wear can contribute to a longer service life. Valves that require minimal maintenance not only help in lowering operational costs but also enhance overall efficiency.

Longevity in valve selection is also closely linked to the operating environment. Understanding the specific conditions—such as temperature fluctuations, pressure levels, and the type of media being controlled—can guide choices that avoid premature failure. It is advisable to consider technologies that incorporate self-regulating features or those that offer enhanced durability under stress. Investing in high-quality manufacturing processes and designs will assure that the valves perform reliably over time, minimizing the frequency and cost of replacements. By focusing on these aspects in your selection process, you can ensure that the valves not only meet current application needs but also stand the test of time in demanding industrial settings.

Same Day Shipping

ISO Certified Production