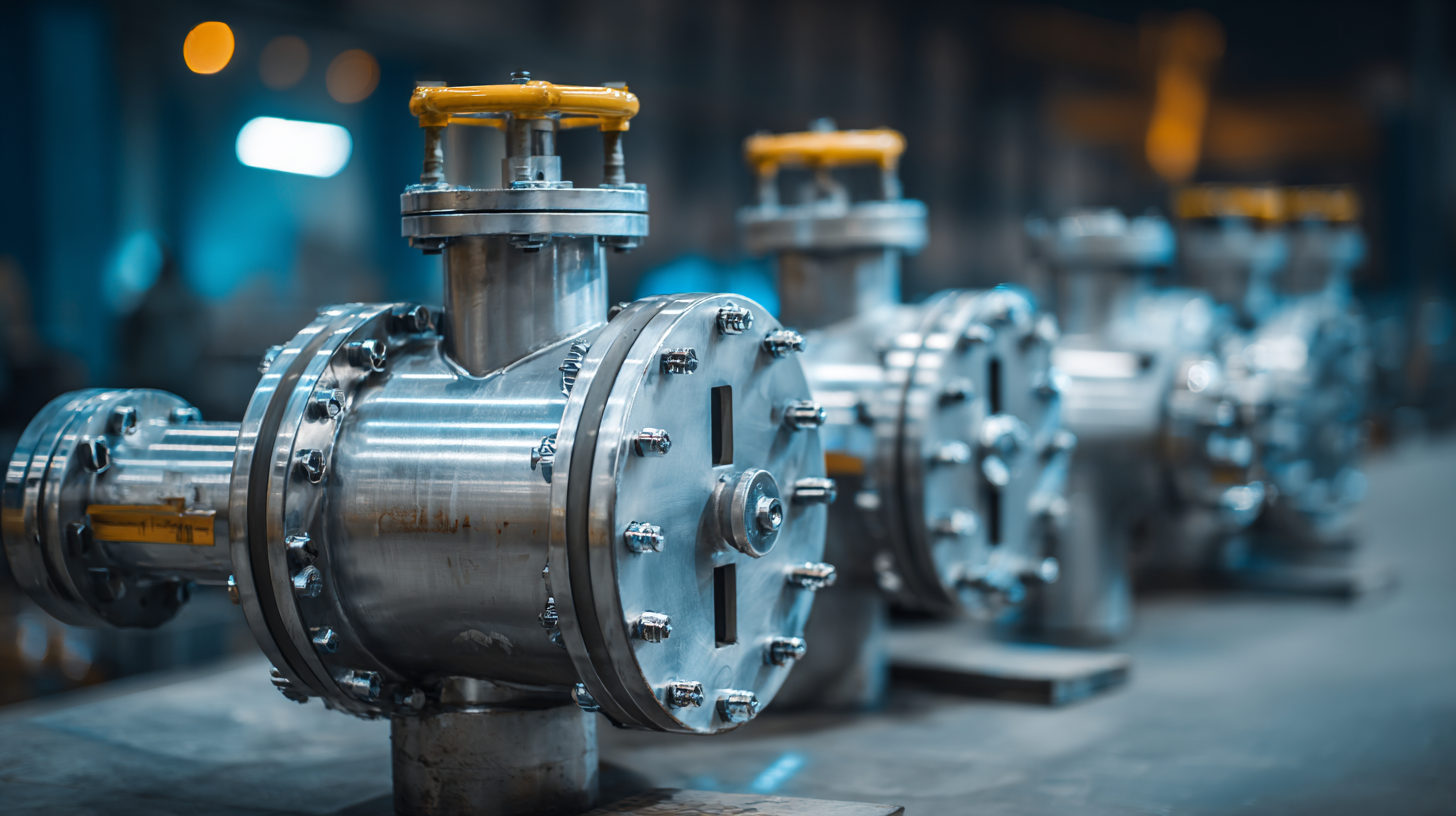

When selecting the best wafer butterfly valve for your industrial needs, it's essential to understand the critical role these components play in fluid control systems. According to a recent report by Market Research Future, the global valve market is anticipated to reach USD 100 billion by 2025, with butterfly valves, particularly wafer butterfly valves, experiencing significant growth due to their lightweight and cost-effective design. These valves are ideal for various applications, including water treatment, oil and gas, and chemical processing, as they provide efficient throttling capabilities and excellent flow control. However, the selection process can be daunting, given the myriad of options available. This blog aims to equip you with an ultimate checklist tailored to guide you in making an informed decision while addressing your specific industrial requirements.

Wafer butterfly valves are increasingly becoming essential components in various industries, known for their lightweight design and space-saving benefits. Industries such as water treatment, oil and gas, and food processing rely heavily on these valves for their efficiency and reliability. According to a report by MarketsandMarkets, the global butterfly valve market is expected to reach $8.2 billion by 2025, with a significant portion attributed to the rising demand in these critical sectors. The simplicity and versatility of wafer butterfly valves make them ideal for controlling flow and pressure in multiple applications, enhancing system performance and energy efficiency.

In the oil and gas sector, for instance, wafer butterfly valves play a pivotal role in both upstream and downstream processes. Their ability to function effectively in high-pressure environments makes them preferred choices for pipeline applications. A study from Grand View Research indicates that the oil and gas industry will continue to dominate the butterfly valve market, accounting for over 30% of the total share by 2026. Meanwhile, in water treatment facilities, the corrosion-resistant properties of these valves ensure long-lasting performance, even in aggressive environments. Businesses in these industries are turning towards wafer butterfly valves to optimize operational performance and minimize maintenance costs, reflecting the growing trend of integrating advanced valve technologies into existing systems.

Selecting the right wafer butterfly valve for industrial applications can be fraught with challenges. One of the most common obstacles is understanding the specific requirements of your system, including pressure, temperature, and flow characteristics. Many engineers underestimate the impact of these factors, which can lead to valve failure or inefficient operation. It's essential to conduct a thorough analysis of your system's needs to ensure that the selected valve will perform optimally under the given conditions.

Another challenge is material selection, as wafer butterfly valves come in various materials, each suited to different media types and environmental conditions. Failing to choose the right material can result in corrosion, leakage, or premature wear. Additionally, compatibility with existing pipeline systems is crucial; the valve must fit seamlessly into the current design to avoid operational disruptions. By carefully considering these factors, industrial professionals can navigate the complexities of selecting wafer butterfly valves and ensure reliable performance in their applications.

| Criteria | Considerations | Common Challenges |

|---|---|---|

| Material Compatibility | Ensure the valve material is suitable for the fluid type and environmental conditions. | Mismatch between valve material and process fluids can lead to corrosion or failure. |

| Size and Dimensions | Select a valve size that fits the pipe diameter and system design. | Incorrect sizing can cause flow restrictions or excessive wear. |

| Pressure Rating | Verify the valve's pressure rating meets the system requirements. | Valves not rated for high pressure may fail under operational conditions. |

| Actuation Type | Decide between manual, electric, or pneumatic actuation based on application needs. | Choosing the wrong actuation can impact operational efficiency. |

| Flow Control | Assess how precisely the valve can control flow rates required for your process. | Inadequate flow control can affect system performance. |

| Installation Requirements | Understand the installation process and any specific tools or skills required. | Improper installation can lead to leaks and system failures. |

| Maintenance Needs | Evaluate the frequency and complexity of maintenance required for the valve. | Lack of maintenance can result in reduced lifespan and reliability. |

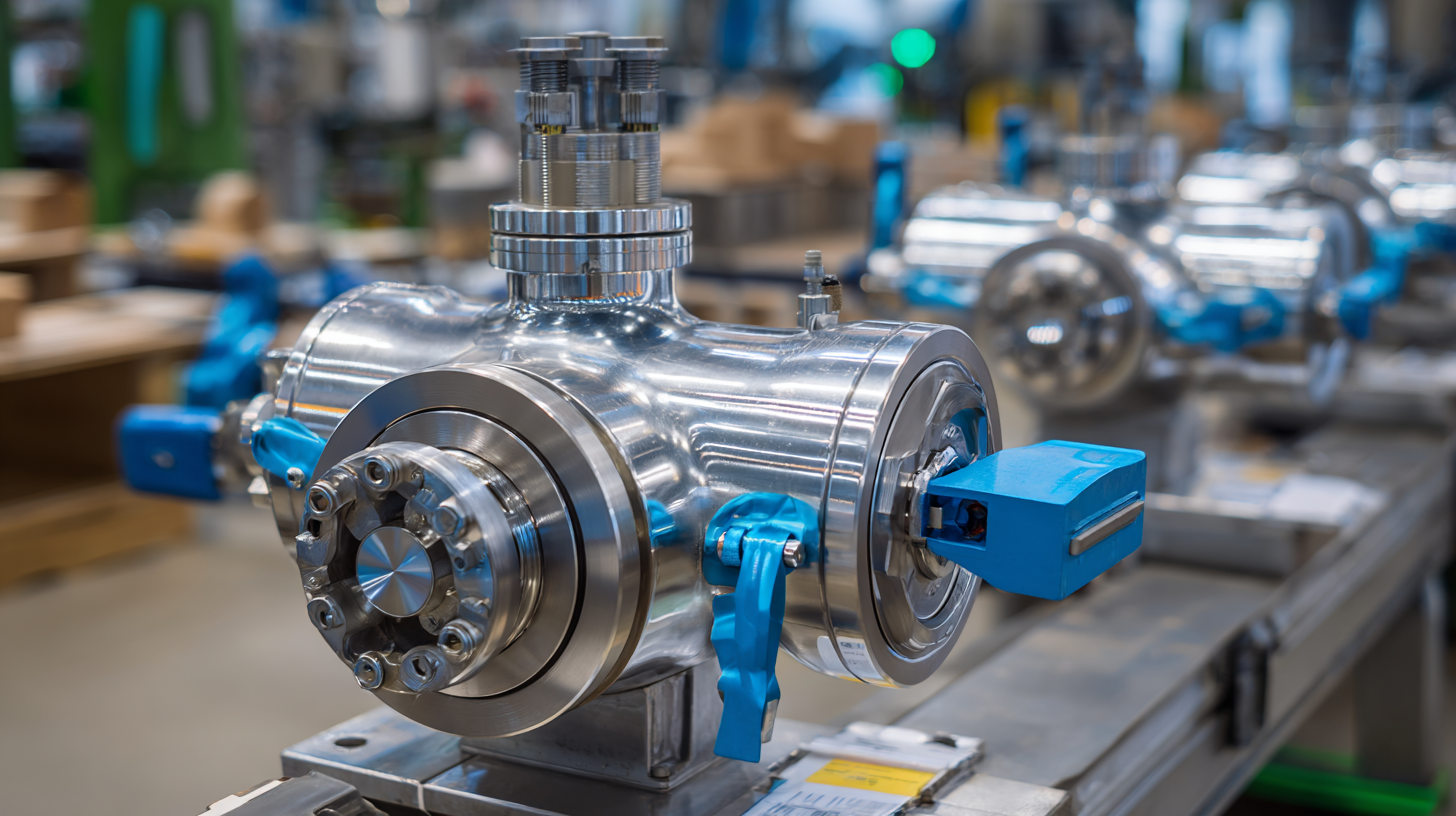

When selecting the best wafer butterfly valve for industrial applications, it’s essential to consider several key features that determine performance and reliability. According to a recent report from MarketsandMarkets, the industrial valves market is projected to reach $85.6 billion by 2027, indicating a growing demand for high-quality components like wafer butterfly valves. These valves should offer robust construction, often made from stainless steel or ductile iron, to endure the pressures and corrosive environments typical in industrial settings.

Another critical feature is the valve's seating design. High-performance wafer butterfly valves typically utilize advanced elastomeric or metal seats, enhancing their sealing capability and longevity. It’s also vital to assess the valve’s diameter and pressure rating to ensure compatibility with the system. A study highlighted that proper sizing can improve system efficiency by up to 20%, making it a crucial consideration in the selection process.

Tips: Always verify the manufacturer's certifications and warranty information. Opt for valves that meet industry standards such as ISO or API. Additionally, examine the ease of maintenance and availability of spare parts, as these factors can significantly impact long-term operational costs and reliability.

When considering the selection of wafer butterfly valves for industrial applications, it's essential to analyze their various types and pertinent applications. The market for electrically actuated butterfly valves is projected to see significant growth, with sales volume and price analyses estimating expanding demand in sectors that require efficient fluid control solutions. The comparison between different types, particularly between wafer-style valves and traditional globe valves, has become increasingly relevant, especially within utility services in industries like offshore operation, where maintenance and reliability are critical.

Recent studies suggest that wafer butterfly valves can serve as effective replacements for straight pattern globe valves, particularly in utility services where space and weight savings are essential. Additionally, the global plastic wafer butterfly valve market is on an upward trajectory, driven by advantages like corrosion resistance and lower weight compared to metal alternatives. Industry reports indicate that manual and pneumatic butterfly valves find extensive use in applications such as water treatment and pulp industries, making them pivotal for achieving operational efficiency and environmental compliance. As the demand for innovative solutions evolves, understanding the comparative advantages of these valves will aid decision-makers in selecting the best option for their specific industrial needs.

When choosing the best wafer butterfly valve for your industrial needs, it is crucial to address common problems that can arise during use. The plastic wafer butterfly valve market is projected to see significant growth, rising from USD 1.2 billion in 2024 to USD 2.5 billion by 2033. This rapid expansion, driven by increasing demand for efficient flow control solutions, emphasizes the importance of selecting the right valve to prevent issues such as leakage and poor performance under varying pressure conditions.

Moreover, the global butterfly valve market as a whole is expected to grow at a compound annual growth rate (CAGR) of 5%, reaching a valuation of USD 18.4 billion by 2034, up from USD 11.3 billion in 2024. This trend indicates that industries are increasingly recognizing the advantages of wafer butterfly valves in comparison to traditional options. Additionally, recent studies suggest that wafer butterfly valves can serve as effective replacements for globe valves in specific utility applications, providing superior flow regulation and easier maintenance. By understanding these market dynamics and the specific applications of wafer butterfly valves, users can make informed decisions to optimize their industrial processes.

Same Day Shipping

ISO Certified Production