In the realm of fluid control systems, the "ball check valve" plays a pivotal role in ensuring efficiency and reliability. These devices work by allowing fluid to flow in one direction while preventing backflow, thereby safeguarding the integrity of various systems. As John Smith, a renowned fluid dynamics engineer, aptly puts it, “The simplicity and effectiveness of a ball check valve make it an indispensable component in modern fluid control applications.”

This valuable insight highlights the myriad advantages that ball check valves offer across a wide range of industries. From minimizing potential system damage caused by reverse flow to enhancing overall operational efficiency, these valves prove essential in countless applications. In this article, we will delve into the top ten benefits of using ball check valves, underscoring their significance in optimizing fluid control systems and ensuring seamless performance.

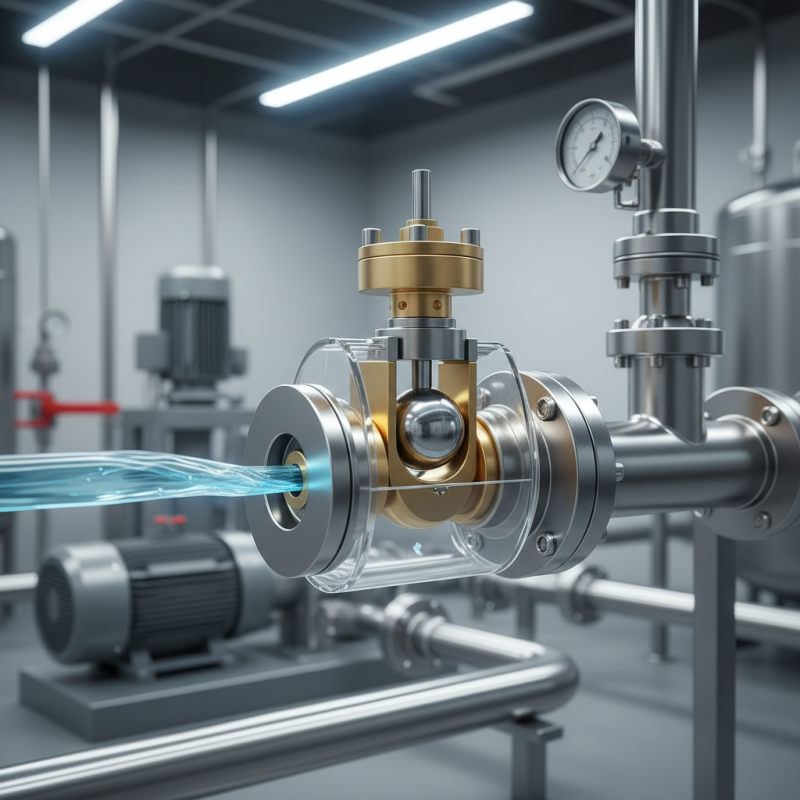

Ball check valves are essential components in fluid control systems, widely recognized for their reliability and efficiency in preventing backflow. These valves operate using a spherical ball that moves in response to fluid pressure. When fluid flows in the intended direction, the ball is pushed away from the seat, allowing passage. Conversely, when back pressure occurs, the ball is pressed against the seat, effectively sealing the valve and preventing reverse flow. According to a 2021 report by the Fluid Control Association, utilizing ball check valves can enhance system efficiency by up to 20%, minimizing the risk of contamination and operational disruptions.

The design of ball check valves allows for minimal pressure drops across the valve, an advantage that contributes to maintaining the overall efficiency of fluid control systems. This is particularly important in applications like wastewater management and chemical processing, where maintaining a consistent flow is critical. A technical study indicated that systems incorporating ball check valves exhibited a 30% decrease in energy consumption compared to those using traditional gate or globe valves. With their self-cleaning capabilities, ball check valves also reduce maintenance costs, as their design minimizes the accumulation of debris, further enhancing the durability and lifespan of fluid systems.

| Benefit | Description |

|---|---|

| 1. Prevents Backflow | Ball check valves effectively prevent the reverse flow of fluids in pipelines. |

| 2. Simple Design | Their straightforward design allows for easy installation and maintenance. |

| 3. High Flow Capacity | Offers a high flow capacity with minimal pressure drop across the valve. |

| 4. Versatile Applications | Applicable in various industries including water treatment, oil and gas, and HVAC. |

| 5. Durable Materials | Constructed from robust materials to withstand harsh environments. |

| 6. Low Maintenance | Requires less maintenance compared to other types of check valves. |

| 7. Minimal Turbulence | Helps to maintain steady flow and reduces turbulence at the valve. |

| 8. High Resistance to Temperature | Can operate effectively in a wide range of temperatures. |

| 9. Easy to Automate | Compatible with various automation systems for enhanced control. |

| 10. Cost-Effective Solution | Provides an economical choice for flow control applications. |

Ball check valves play a crucial role in fluid control systems, providing key advantages that enhance their functionality and reliability. One of the primary benefits is their simplicity in design, which allows for easy installation and maintenance. Unlike other valve types, ball check valves operate using a floating ball mechanism that automatically seals against the valve seat when backflow occurs. This design minimizes the risk of leaks, ensuring efficient operation and reducing the need for frequent servicing.

Moreover, ball check valves are highly durable and capable of withstanding a variety of pressures and temperatures, making them suitable for diverse applications. Their ability to handle turbulent flow without performance degradation is another significant advantage. This characteristic ensures smooth fluid dynamics and minimizes wear and tear on the system components, which can extend the overall lifespan of the fluid control system. Additionally, these valves provide excellent flow characteristics, ensuring that fluid can move freely in the designated direction while preventing backflow, which is critical for maintaining system integrity and performance.

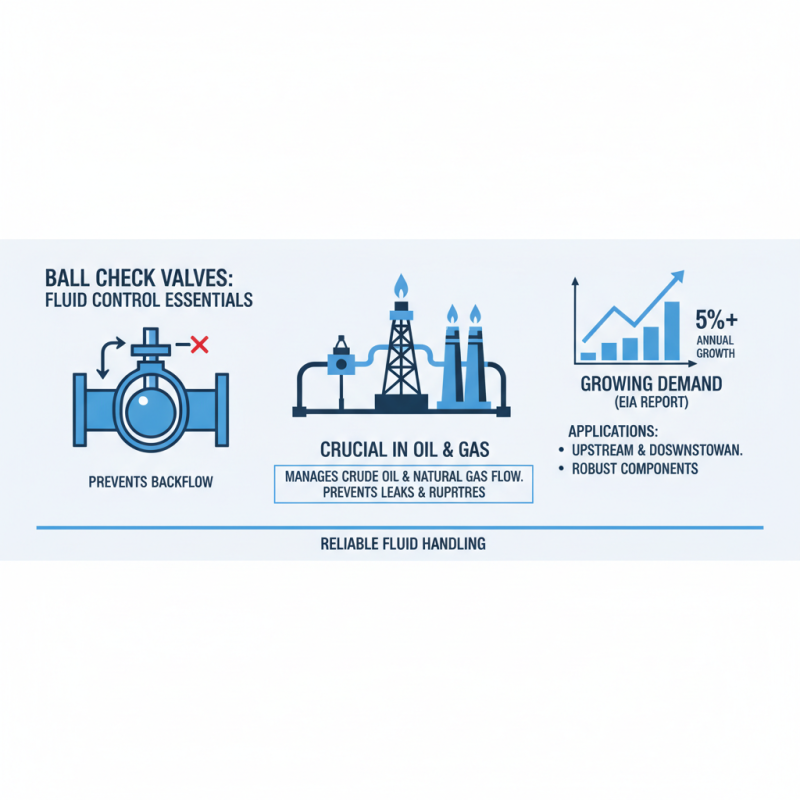

Ball check valves play a crucial role in fluid control systems across various industries, providing a reliable means of preventing backflow while allowing fluid to flow in a designated direction. In the oil and gas sector, for instance, these valves are essential for managing the flow of crude oil and natural gas, ensuring that pressure surges do not result in dangerous leaks or ruptures. According to a report by the Energy Information Administration, the demand for efficient fluid handling systems in upstream and downstream activities is projected to grow by over 5% annually, underscoring the importance of robust components like ball check valves.

In the water treatment industry, ball check valves are vital in ensuring the integrity of water supply systems. These valves safeguard against contamination and backflow, maintaining the purity of potable water. The global water treatment equipment market, valued at approximately $45 billion in 2022, is expected to expand by 7% each year, driven by the need for sustainable water management practices. This growth highlights the increasing reliance on dependable technologies, such as ball check valves, to enhance system performance and reliability in various fluid handling applications. Whether in chemical processing or irrigation systems, these valves serve as a critical element in safeguarding operations and ensuring compliance with regulatory standards.

When evaluating the efficacy of ball check valves in fluid control systems, a comparative analysis with other types of check valves reveals distinct advantages. Ball check valves feature a simple design that allows for minimal pressure loss and efficient flow. Unlike swing check valves, which can be hindered by the weight of the valve disc, ball check valves utilize a freely moving ball that responds immediately to changes in flow direction, ensuring a reliable seal and reducing the risk of backflow. This responsiveness makes them particularly suitable for systems where quick adjustments in fluid dynamics are essential.

In contrast, diaphragm check valves, while effective, can have more complex mechanisms that may result in slower response times and increased wear over time due to the flexing of their diaphragm. Furthermore, in applications with varying fluid velocities, ball check valves maintain their integrity better than spring-loaded check valves, which can be prone to failure if the spring mechanism becomes compromised. The inherent simplicity and reliability of ball check valves position them as a preferred choice in many fluid control applications, emphasizing their advantages through this comparative lens.

This chart compares the benefits of ball check valves against other types of check valves. The data illustrates the effectiveness and reliability of ball check valves in various applications.

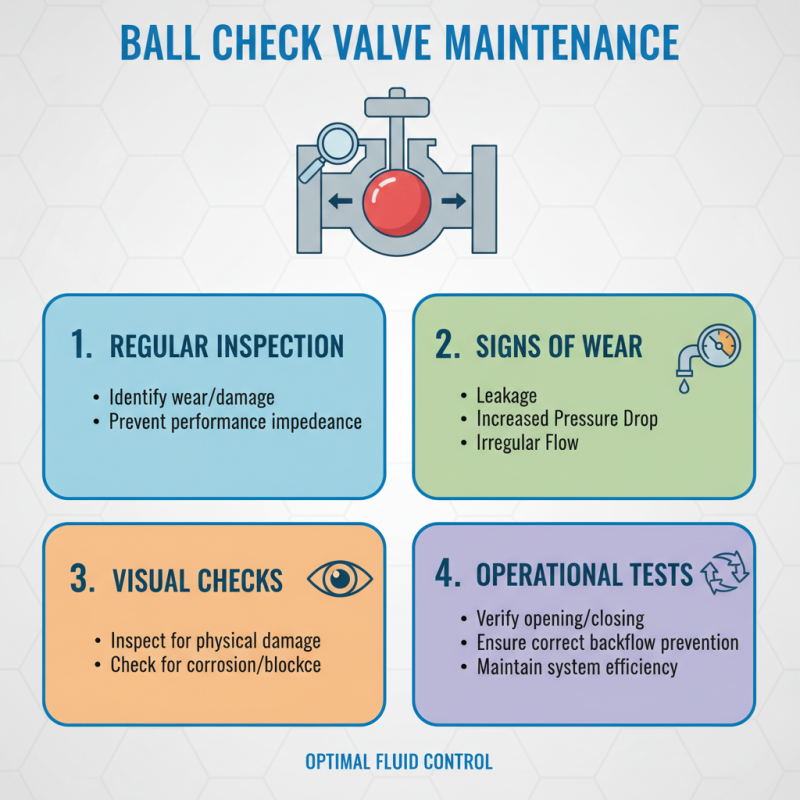

When it comes to the maintenance of ball check valves, there are several crucial considerations to ensure their optimal functionality in fluid control systems. Regular inspection is essential to identify any wear or damage that may impede performance. Signs of wear can include leakage, increased pressure drop, or irregular flow patterns. Visual checks should be complemented by operational tests to verify that the valve opens and closes correctly, which is critical for preventing backflow and maintaining system efficiency.

Proper installation and regular maintenance schedules are vital for extending the lifespan of ball check valves. Periodic cleaning is necessary to remove buildup from the valve's interior that could block flow or cause mechanical failure. Furthermore, lubricating the moving parts helps reduce friction and wear, promoting smoother operation. It's also advisable to keep a record of maintenance activities, including when inspections and repairs were performed, to help predict future service needs and identify recurring issues. With diligent attention to these maintenance practices, ball check valves can perform reliably, ensuring effective fluid control.

Same Day Shipping

ISO Certified Production