The triple offset butterfly valve is a critical component in various industries. Its unique design sets it apart from standard valves. This valve features three offsets, which enhance its sealing capabilities and provide a tight shut-off.

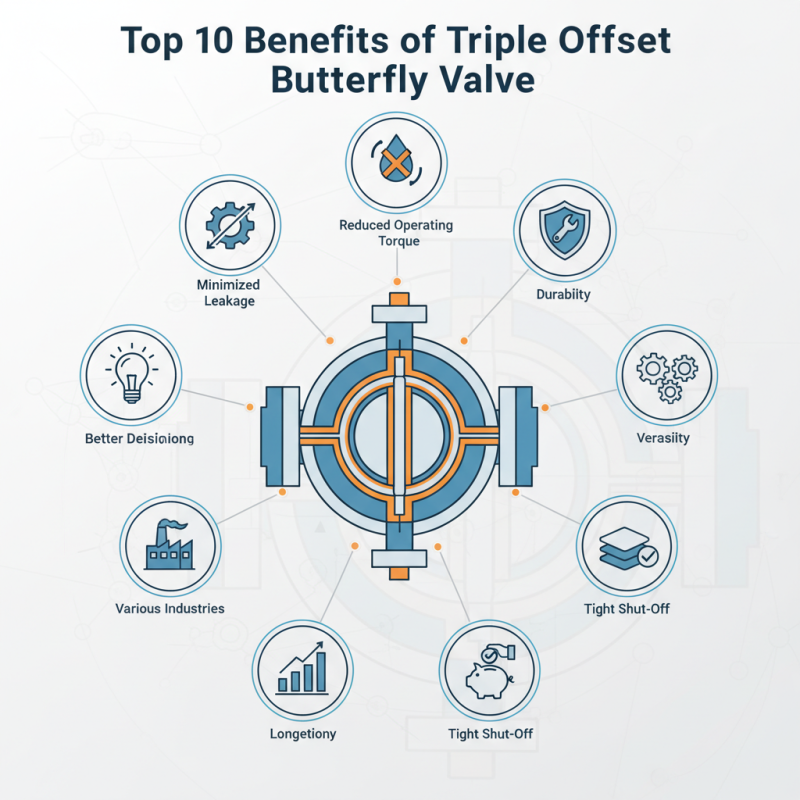

A triple offset butterfly valve effectively minimizes leakage. This design also reduces operating torque, making it easier to control. Industries rely on its durability and versatility. However, some users may encounter challenges with installation and maintenance.

Understanding these aspects is crucial. The benefits of the triple offset butterfly valve go beyond simple operation. They include longevity and cost-efficiency in the long run. Exploring these advantages can lead to better decision-making in valve selection.

Triple Offset Butterfly Valves are essential in many industrial applications. Their unique design offers significant advantages over traditional valves. These valves have three distinct offsets that create a sealing mechanism. This design helps reduce friction and wear.

One major benefit is their ability to handle high pressures. They maintain a tight seal, which minimizes leakage. This makes them ideal for critical operations. Additionally, they offer lower torque requirements. Operators find them easier to control using less force.

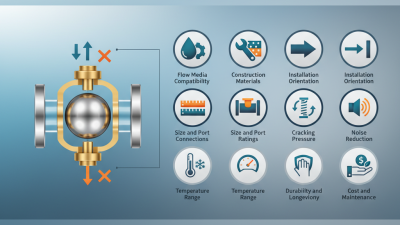

Tips: When selecting a valve, consider the application carefully. Understand the pressure and temperature conditions. This ensures you choose the right material and design. Also, regular maintenance is crucial for peak performance. Ignoring this can lead to unexpected failures.

Another aspect worth noting is the lifespan of these valves. Though they may be more expensive initially, they provide excellent longevity. This can result in lower overall costs. Ensure proper installation to maximize these benefits. In some cases, installation requires specialized knowledge.

In conclusion, the triple offset butterfly valve is a valuable asset in various systems. They optimize performance and durability. However, it's important to weigh the benefits and challenges for your specific use case.

| Benefit | Description |

|---|---|

| High Tightness | Ensures minimal leakage and reliable sealing due to its unique design. |

| Long Lifespan | Constructed from durable materials that enhance operational longevity. |

| Low Torque | Requires less force to operate, improving efficiency and reducing wear. |

| Easy Operation | Simplifies the process of opening and closing due to its design. |

| Versatile Applications | Can be used in a wide range of industries including oil & gas, water treatment, and HVAC. |

| Compact Design | Space-saving installation is possible due to its efficient structure. |

| Reduced Maintenance | Lower maintenance requirements result in cost savings over time. |

| Enhanced Performance | Optimized flow characteristics lead to better system performance. |

| Culture of Safety | Improved safety features reduce the risk of system failures. |

| Cost-Effective | Offers a valuable balance of performance and cost, making it an economical choice. |

Triple offset butterfly valves offer a range of significant advantages, making them a popular choice in various industries. One key advantage is their design, which ensures a tight seal. This design minimizes leakage, enhancing efficiency in fluid control. The unique geometry allows for a smooth flow path, reducing turbulence. As a result, these valves contribute to better performance and energy savings.

Another benefit lies in their durability. Triple offset valves are designed to withstand high pressures and temperatures. This durability reduces the need for frequent replacements, saving costs over time. They also require less maintenance, which can be a game-changer for many facilities.

Tips: When selecting a valve, consider the specific application. Assess the fluid characteristics and operational conditions. This will help ensure you choose the right valve for optimal performance. It’s essential to involve your engineering team. Their insights can lead to better decision-making.

Choosing the right materials for construction can also impact performance. Stainless steel or special alloys may be necessary for harsh environments. Reflection on past valve failures can guide future purchases. Avoiding previous mistakes can improve reliability and safety.

When it comes to sealing performance, triple offset butterfly valves stand out. Their unique design minimizes leakage, making them ideal for critical applications. According to a report by the International Society of Automation, leakage in valve systems can account for up to 30% of inefficiencies in industrial processes.

The triple offset design features three mechanical offsets, allowing for a smoother disk movement. This reduces friction and increases longevity. Studies illustrate that these valves can maintain tight seals even under high pressure and extreme temperatures. For instance, tests show they can handle pressures up to 30% higher than conventional valves, ensuring reliability in various conditions.

However, there are challenges. The complexity of their design may lead to higher initial costs and maintenance challenges. Many engineers must consider the trade-off between upfront investment and long-term savings. Moreover, the need for specialized training can complicate installation and repairs. These aspects highlight that while triple offset butterfly valves offer enhanced performance, users should be aware of the investment and skill requirements.

Triple offset butterfly valves are widely used in various industries due to their versatility and efficiency. These valves are commonly found in oil and gas, water treatment, and chemical processing sectors. They handle high-pressure applications effectively. This design also ensures tight sealing, making them ideal for flow control.

In oil and gas, these valves are crucial for managing flow in pipelines. They can withstand harsh conditions, which is vital for safety. Water treatment facilities utilize these valves to regulate water flow efficiently. Their ability to minimize leakage is essential, especially when dealing with potable water.

Tip: When selecting a triple offset valve, consider the specific application requirements. Check pressure ratings, and flow rates, and pay attention to the operating conditions.

In the chemical processing industry, these valves’ resistance to corrosive fluids is a plus. However, improper installation can lead to inefficiencies. Regular maintenance is critical for extending their lifespan. With proper care, downtime can be minimized.

Tip: Always follow the manufacturer’s guidelines for installation and maintenance. This can save time and costs in the long run.

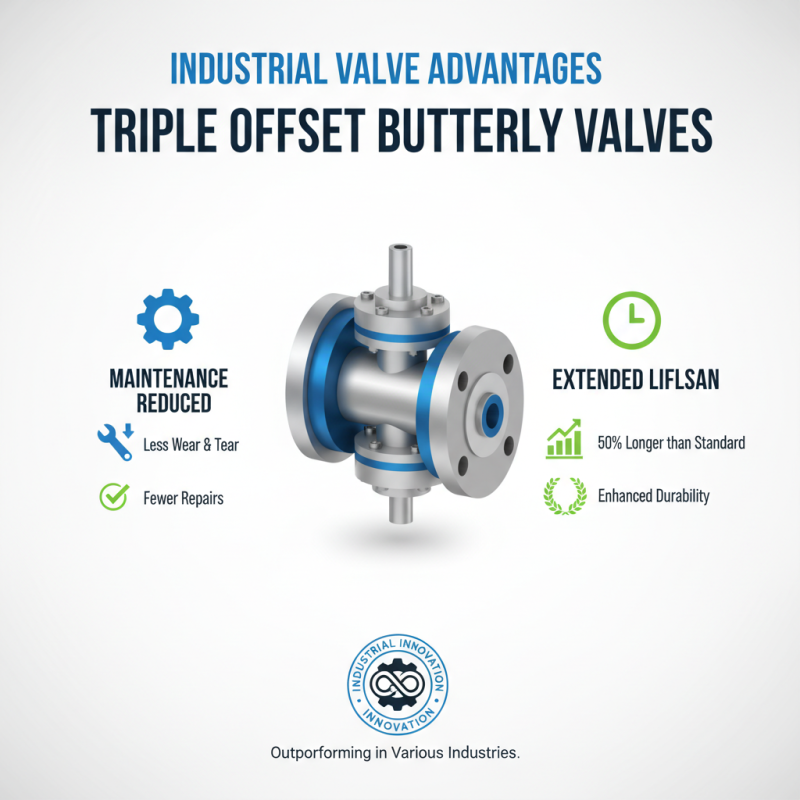

Triple offset butterfly valves are increasingly recognized for their maintenance advantages and long lifespan. In various industries, these valves typically last longer than traditional ones. A study showed that they can outlast standard butterfly valves by 50%. Their design minimizes wear and tear, reducing the need for frequent repairs.

Routine maintenance is also simpler with these valves. They often feature fewer parts, which leads to lower downtime. According to industry data, a well-maintained triple offset valve can operate efficiently for over 20 years. However, neglecting maintenance can reduce this lifespan significantly. Regular inspections help identify issues before they escalate.

Despite their benefits, some maintenance challenges exist. Installing triple offset valves requires specific expertise. Misalignment during installation can lead to performance issues. Training staff is essential for ensuring proper handling and maintenance. Reflecting on these factors helps industry professionals make informed decisions about valve selection.

Same Day Shipping

ISO Certified Production