In the world of fluid control, the significance of check valves cannot be overstated. Industry expert Mark Johnson, a veteran in valve technology, once stated, "Check valves are the backbone of safe fluid movement." These components ensure that fluids flow in one direction, preventing backflow and protecting systems from potential damage.

The 2026 market for check valves is evolving rapidly. New designs and materials are entering the industry. Manufacturers are focusing on efficiency and reliability. There’s a constant search for innovations that improve performance. However, not all check valves meet these evolving standards. Some may falter under pressure or fail to seal properly. This inconsistency can lead to costly issues.

Understanding the diverse options available is crucial. Different applications may require different types of check valves. A lack of knowledge can lead to poor choices. As end-users, scrutiny is essential. Researching specifications, materials, and reliability ratings can make a difference. With a myriad of choices, being informed is key to success in using check valves effectively.

Check valves play a crucial role in various industries. These devices allow fluid to flow in one direction while preventing backflow. They are essential in maintaining system efficiency and safety. A report by Research and Markets indicates that the global check valve market is projected to reach $8.04 billion by 2025, growing at a rate of over 6% annually.

In sectors like oil and gas, check valves ensure operational reliability. They prevent hazardous leakage and protect equipment from damage. In water treatment facilities, these valves help manage flow and pressure effectively. However, not all installations perform as expected. Over time, valve deterioration can lead to failures, provoking significant downtime. Maintenance schedules often overlook these critical components.

User feedback often highlights issues such as misalignment or wear. These problems can compromise system integrity. Regular inspections are necessary, yet they are frequently neglected. Understanding the stressors on check valves can guide better design and operational practices, leading to increased reliability and lower costs.

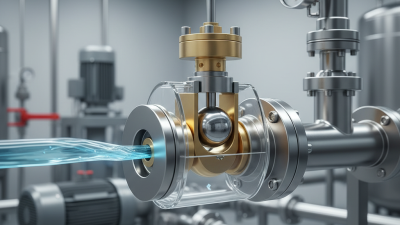

Check valves play a crucial role in various applications. They allow fluid to flow in one direction while preventing backflow. Understanding the types of check valves can help you choose the right one for your needs.

There are several key types of check valves. Swing check valves are ideal for low-pressure applications. Their design allows a disc to swing open and close, ensuring proper flow. On the other hand, lift check valves work under high pressure. They use a piston that rises and falls, reacting quickly to changes in flow.

Tips: Consider the application to select the valve type. Low pressure, choose swing valves. High pressure, opt for lift valves.

Another type is ball check valves. They contain a ball that moves with fluid flow. This design offers reliability in preventing backflow. However, they may not work well in all situations. Their performance can vary based on pressure and fluid characteristics.

Tips: Regular maintenance is vital. Inspect valves for wear. Replace them if necessary to ensure efficiency.

| Valve Type | Features | Applications |

|---|---|---|

| Swing Check Valve | Offers low-pressure drop, good for horizontal pipelines | Water supply, HVAC systems |

| Lift Check Valve | Compact design, suitable for high-pressure applications | Oil and gas industry, nuclear power plants |

| Dual Plate Check Valve | Lightweight and quick operation, minimizes turbulence | Chemical processing, water treatment |

| Ball Check Valve | Self-cleaning mechanism, good for slurry services | Mining, power generation |

| Spring Loaded Check Valve | Pre-loaded mechanism, ensures a tighter seal | Pumping systems, fire protection |

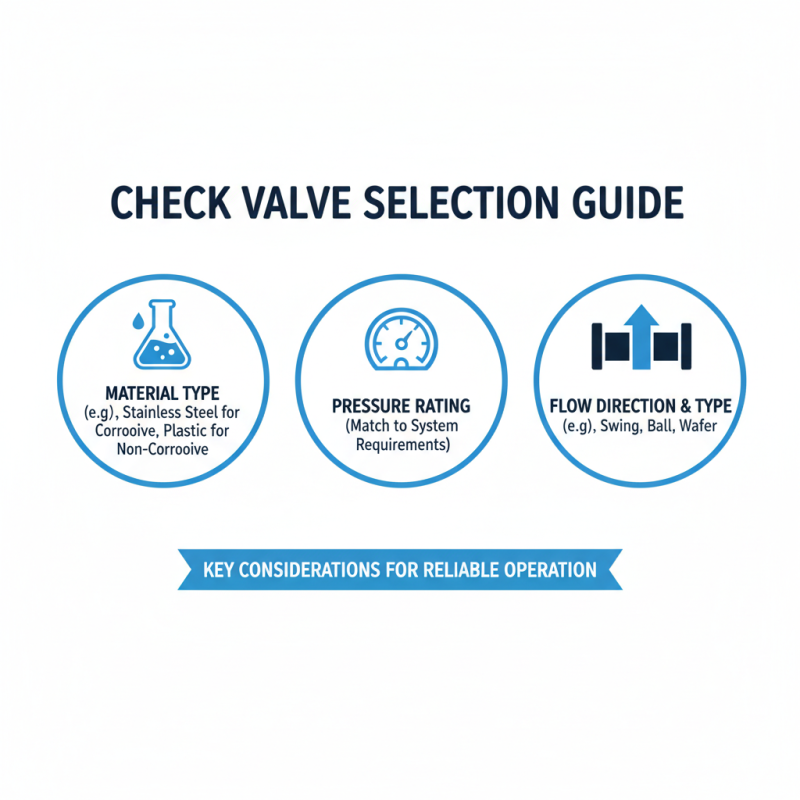

When selecting check valves, there are several critical factors to consider. The valve's material is essential. Different applications require different materials. For example, stainless steel is ideal for corrosive environments. Plastic might be suitable for less demanding tasks. The pressure rating also plays a crucial role. It determines how much pressure can be safely handled. Choosing a valve with an inadequate rating can lead to failure.

Flow direction is another vital aspect. Check valves are designed for one-way flow. Installing them incorrectly can cause backflow issues. Size matters as well. A valve that is too small can restrict flow. Conversely, an oversized valve may not seal properly.

It's also important to consider maintenance needs. Some valves require more attention than others. Simplicity in design can lead to greater reliability. However, more complex designs might offer better performance. Deciding between these options deserves careful thought. Be sure to analyze specific requirements closely.

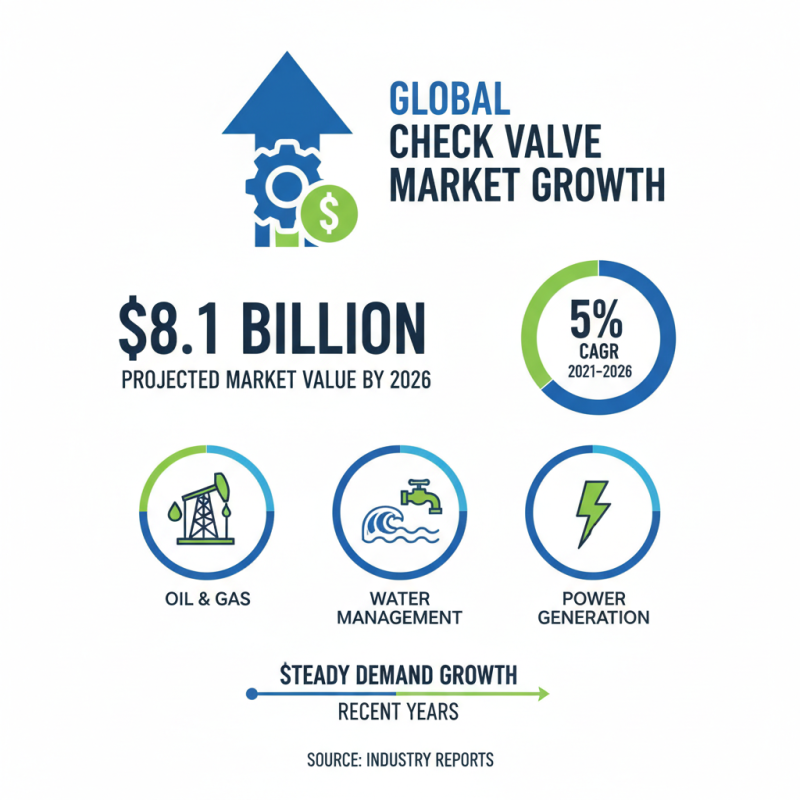

The demand for check valves has seen steady growth in recent years. According to industry reports, the global check valve market is projected to reach $8.1 billion by 2026, with a compound annual growth rate (CAGR) of 5% during the forecast period. This indicates a strong interest from various sectors, including oil and gas, water management, and power generation.

Top manufacturers are focusing on innovation to meet specific needs. For instance, the trend towards eco-friendly materials is reshaping production processes. Some companies are investing heavily in research and development to create more efficient and reliable products. This shift aims to address challenges such as leakage and material degradation that many users face. Interestingly, the adaptability of check valves across several applications is often overlooked.

However, the industry still has hurdles to overcome. Quality control and inconsistent manufacturing standards pose challenges. These issues can lead to product failures, impacting operational efficiency for end-users. Additionally, a lack of awareness about the latest technologies among some manufacturers may hinder market growth. This gap reveals opportunities for education and improvement in the sector.

As the industry evolves, check valve technology is also advancing. Innovations such as smart sensors are becoming more common. These devices can monitor valve performance real-time. This data allows for proactive maintenance. It helps prevent costly failures down the line.

Tips: Consider the installation environment. Choose valves that suit your specific application needs. Pay attention to the material of the valve. This choice can impact performance and longevity significantly.

Future developments may focus on improving efficiency. Manufacturers are exploring materials that reduce wear and tear. Additionally, automation in check valves is on the rise. This technology can streamline operations. However, not all innovations are perfect. Testing remains crucial to ensure reliability in various conditions.

Same Day Shipping

ISO Certified Production