In the realm of industrial operations, selecting the right components is crucial. Among these, industrial valves play a vital role. They control the flow and pressure of various substances, ensuring efficient processes. Understanding the best options available for 2026 is essential for any industry leader.

Today’s market offers a diverse range of industrial valves. Each type serves specific functions in different environments. For example, ball valves provide quick shut-off, while gate valves are ideal for on/off control. Selecting the wrong valve can lead to inefficiencies. Sometimes, the cheapest option costs more in the long run.

As industries evolve, so do the technologies behind industrial valves. Keeping up with innovations is a challenge. It’s easy to overlook certain features. Valves that don’t fit well with existing systems can lead to increased downtime. Evaluating the efficiency of these components is critical for long-term success. Choosing wisely can make or break operational efficiency.

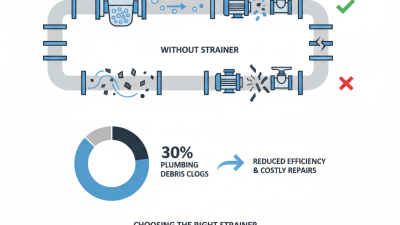

Industrial valves are crucial components in various sectors, influencing overall efficiency and safety. According to a recent report from the Global Industrial Valve Market, these valves constitute about 20% of total equipment costs in industrial systems. Properly functioning valves ensure the smooth operation of flows, controlling liquids and gases across processes. Mismanaged valves can lead to significant operational disruptions. For instance, a 2019 study showed that 15% of unscheduled downtime in manufacturing could be attributed to valve failures.

The importance of selecting the right valves cannot be overstated. Different types serve specific functions, like isolation, control, and pressure relief. The same report suggests that around 25% of process industries do not regularly assess their valve performance. This oversight can lead to inefficiencies and increased energy costs. Proper maintenance and selection often reduce operational waste by 10-15%, demonstrating the need for systematic monitoring.

Moreover, digitalization is impacting valve management. Many plants are still not utilizing smart technologies for real-time monitoring. This gap can result in costly overhauls or replacements down the line. While the shift towards more intelligent solutions is evident, a substantial number of facilities remain hesitant to invest. Effective valve management is a continual process requiring awareness, assessment, and adaptive strategies for true operational success.

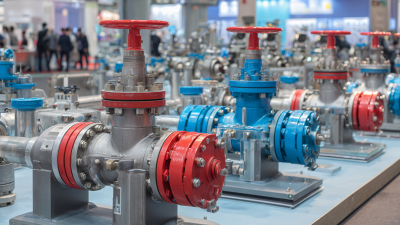

In industrial settings, choosing the right valves is crucial for operational efficiency. Several types of valves can enhance performance. Gate valves are often used for on/off applications. They provide minimal resistance, allowing for smooth flow. Ball valves, on the other hand, are known for their excellent sealing capabilities. They are swift to operate, which can save time in critical processes.

Butterfly valves offer a compact design, ideal for tight spaces. They can handle larger volumes of fluids with less power. However, they might not perform well under high pressure. Diaphragm valves are great for handling slurries and corrosive substances. They provide a tight shut-off but may require regular maintenance.

Choosing the right valve involves considering specific operational needs. Many operators underestimate pressure ratings and flow requirements. Using the wrong valve can lead to inefficiencies and costly repairs. Regular assessments of valve performance can reveal areas for improvement. Ensuring the right fit and function is not always straightforward but is essential for efficiency.

| Valve Type | Application | Material | Size Range (inches) | Pressure Rating (PSI) |

|---|---|---|---|---|

| Gate Valve | Isolation | Stainless Steel | 0.5 - 48 | 150 - 2500 |

| Ball Valve | Flow Control | PVC | 0.25 - 12 | 150 - 600 |

| Globe Valve | Regulation | Brass | 0.5 - 10 | 200 - 1500 |

| Check Valve | Backflow Prevention | Ductile Iron | 2 - 36 | 150 - 3000 |

| Butterfly Valve | Flow Regulation | Carbon Steel | 2 - 60 | 150 - 600 |

When selecting industrial valves, several key features should guide your decision. It's crucial to evaluate the material construction. Valves made from robust materials resist corrosion and withstand high pressure. Common materials include stainless steel and cast iron. These options often have longer lifespans, but they can be heavy and more expensive.

Another important aspect to consider is valve size and connection type. Proper sizing ensures seamless integration into piping systems. A mismatch can lead to leaks or inefficiencies. Additionally, check the connection type, whether threaded, flanged, or welded. Each has distinct advantages and limitations.

Don’t overlook the valve's operating mechanism. Options include manual, electric, and pneumatic. Electric valves offer automation but require proper power supply. Manual valves are more straightforward but demand physical effort. Balancing these features against operational needs is essential. Each choice comes with trade-offs that may impact efficiency. Always reflect on how these elements fit into your specific operations.

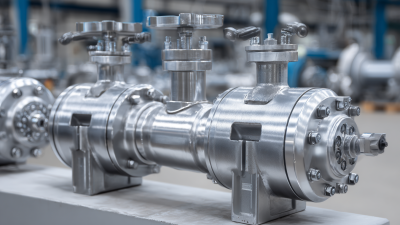

When it comes to industrial valves in 2026, several top brands stand out. These valves enhance efficiency in operations across various sectors. Users prioritize durability and performance, especially in high-pressure environments. Valve types range from ball valves to butterfly valves, each serving unique purposes.

Key features matter. Some valves offer excellent flow control, while others excel in high-temperature situations. Consider the materials used. Stainless steel and plastics are common choices, providing resistance to corrosion. However, some users report issues with maintenance. Sealing problems or leaks can arise unexpectedly.

In selecting the right model, pay attention to specifications. Not all valves are designed equally. Some may not meet your operation’s specific needs. It’s essential to review customer feedback. Real-world experiences reveal both strengths and weaknesses in various models. A careful approach helps avoid costly errors in the long run.

Maintaining industrial valves is crucial for optimal performance. Regular inspections can identify wear and tear before they lead to failures. Check for leaks and unusual noises during operation. These signs often indicate underlying issues. Addressing problems early can save time and costs.

Routine maintenance should include lubrication of moving parts. However, it's critical to use the right lubricants. Incorrect lubricants can cause more harm than good. Inspect seals for damage as well. A worn seal can result in significant product loss and operational inefficiency.

Training staff on proper operation and maintenance is essential. Operators should understand the importance of valves in system efficiency. Misuse can lead to premature failures. Continuous learning helps improve practices over time. Regular audits can also promote a culture of safety and efficiency in valve management.

Same Day Shipping

ISO Certified Production